Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for laser cutting galvanized steel |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Application fields of laser cutting galvanized steel: chassis and cabinet shells for power communication industry, distribution boxes, network chassis, server chassis, standard chassis, communication chassis, power chassis, etc.

It has been widely used in electronic appliances, communications, automobile industry, medical equipment and other fields, such as chassis, cabinets, large racks, etc.

Advantages Light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, good mass production performance, simple processing technology, and can reduce production costs.

Weakness Blanking, punching, trimming, drawing, and flanging products are prone to defect positions.

Wall thickness laser cutting 0.5-10mm; bending 0.5-6mm;

Tolerance cutting ±0.2mm; bending angle ±1.0°; bending to edge ±0.25mm.

Company Information

Meet all the needs of sheet metal processing:

Super fast delivery

For sheet metal proofing orders without special processes, we promise to ship within 7 days. Shorten your R&D cycle and meet your delivery needs.

Process optimization for manufacturability

Senior engineers review the drawings and optimize the process for free based on manufacturability. The cost reduction of mass production is considered in the sample production stage.

Worry-free service

One-to-one professional engineers will dock your order throughout the process and communicate project requirements at any time. Speed up delivery and reduce costs.

Quality Assurance

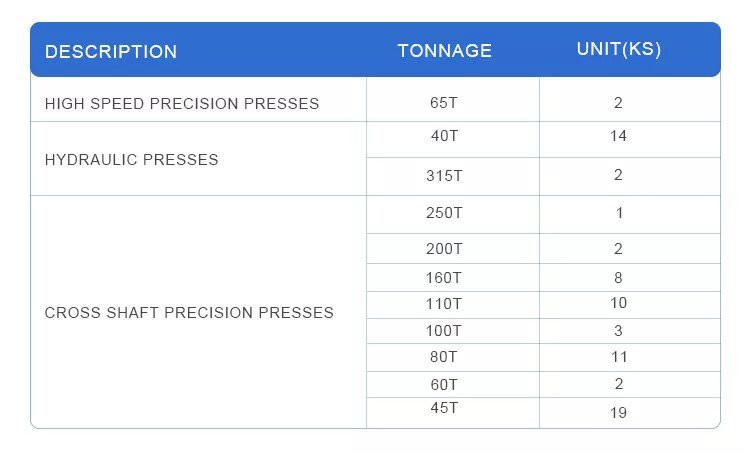

The digital factory closely monitors the production process, equipped with more than 100 sets of high-precision equipment, a professional quality inspection team and complete testing instruments. Your satisfaction is our top priority.

Design service

We will design and customize the products you need according to your samples or sketches. Turn your ideas into reality.

Cost-effective

Smooth process flow, experienced operators, efficient completion of orders, comprehensive cost reduction.

FAQ

Is the sample available?

Yes, we are providing free of samples are available for you to check the quality once confirmed after 1~2 day.

What is your advantage compared with your competitors?

(1). Qualified Manufacturer

(2). Reliable Quality Control

(3). Competitive Price

(4). High Efficiency working (24*7hours)

(5). One-Stop Service

Visting factory is allowed or not?

Yes, we welcome customers visiting our factory. Our factory is located Shenzhen City, Guangdong Province, China mainland.

Hot Tags: laser cutting galvanized steel, China laser cutting galvanized steel manufacturers, suppliers, factory, Cutting And Bending Sheet Metal, Laser Cut Copper Sheet, Laser Cutting Galvanized Steel, Cutting Curves in Sheet Metal