Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for laser cut copper sheet |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Surface treatment of laser cut copper sheet sheet metal processing:

Applicable materials for ordinary anodizing: aluminum alloy-5052, aluminum alloy-1060

Applicable materials for hard anodizing: aluminum alloy-5052, aluminum alloy-1060

Applicable materials for conductive anodizing: aluminum alloy-5052, aluminum alloy-1060

Applicable materials for chrome plating: aluminum alloy-5052, brass-H59, brass-H62, copper-T2, cold-rolled sheet-SPCC, Q235 (A3 steel), 45 steel, aluminum alloy-1060

Applicable materials for galvanizing: aluminum alloy-5052, stainless steel-304, brass-H59, brass-H62, copper-T2, cold-rolled sheet-SPCC, galvanized sheet-SGCC, Q235 (A3 steel), 45 steel, aluminum Alloy-1060, stainless steel-201, electrolytic plate-SECC

Applicable materials for black zinc plating: brass-H59, brass-H62, red copper-T2, cold-rolled sheet-SPCC, Q235 (A3 steel), 45 steel

Company Information

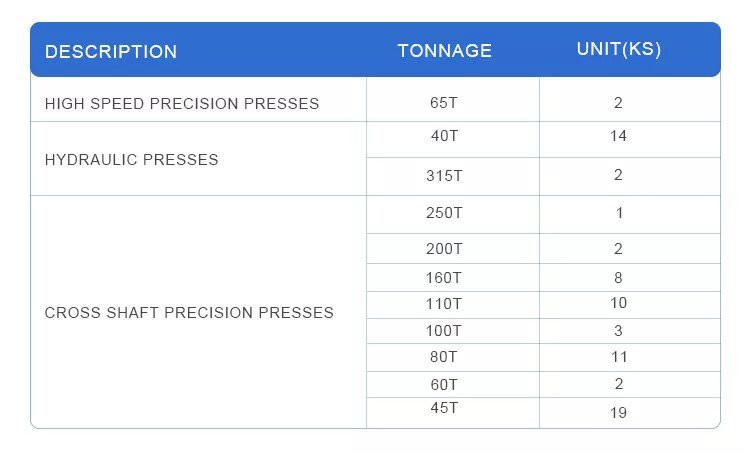

King Siu Metal Products (Shenzhen) Ltd. is a technology-based, equipment-based sheet metal processing and laser cutting manufacturing plant. The company has an excellent geographical environment and is located at No. 10 Pingxi South Road, Xinsheng Community, Longgang District, Shenzhen City, with convenient transportation.

Our company is good at: laser cutting, precision sheet metal, metal products; can cut 0.3-25mm thick carbon steel, stainless steel, copper, aluminum and other metal sheets, pipes; CNC shearing, bending, grooving, punching, Welding processing; professional chassis cabinets, automation equipment production, non-standard customization; undertake design, production, and installation of various stainless steel projects.

After years of development, it has accumulated rich experience in sheet metal processing, advanced equipment, strong technology, and efficient team. Its production scale, technical level and special equipment have reached the advanced level of the same industry, and enjoy a good reputation in the industry. At the same time, we break through the traditional sheet metal processing concept, and have a team proficient in professional design software (Proe, Solid works, AutoCad) to make sheet metal highly flexible from manufacturing to processing, shortening the time from the customer's initial design concept to the product. The well-formed development cycle provides value-added services for product components of local and surrounding enterprises.

We advocate the advanced processing and manufacturing technology in the industry, we pay attention to the requirements of each customer, and wholeheartedly provide customers with solutions that meet the requirements, so that the products we manufacture are perfect.

FAQ

Is there the products tested before shipping?

Yes, of course. All of our conveyor belt we all will has been 100%QC before shipping. We test every batch every day.

How can I get more details about conveyor belt?

1. Email: ks009@kingsiu.com; 2. Visit our factory

What is your MOQ? Can I mix different styles to a start order?

Please tell us what products you need first. Like compression fittings, the MOQ is 100pcs. But we can provide any stock as samples for you to check the quality first.

Can you give me a discount?

Discount is available, but we have to see the real quantity, we have different price based on different quantity, how much discounts is determined by the quantity, moreover, our price is very competitive in the field.

Hot Tags: laser cut copper sheet, China laser cut copper sheet manufacturers, suppliers, factory, Laser Cutting Galvanized Steel, Cutting And Bending Sheet Metal, Cutting Curves in Sheet Metal, Laser Cut Copper Sheet