Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for cutting and bending sheet metal |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

1. With the development of automobile, communication, IT, and daily hardware manufacturing, cutting and bending sheet metal sheet metal processing has become more and more popular, and it becomes more necessary to understand sheet metal processing.

2. The operation of making metal sheets, profiles and pipes into parts with a certain shape, size and precision by manual or mechanical methods is called cutting and bending sheet metal sheet metal processing; in the production of ventilation, air conditioning ducts and their components The application is more extensive.

3. Cutting and bending sheet metal sheet metal parts are mostly made of metal sheets and pipe fittings. Because of its light weight, high strength and rigidity, the shape can be arbitrarily complicated, the material consumption is small, no machining is required, and the surface is smooth and clean. , so it is widely used in daily life and industrial production, such as barrels, basins, ventilation pipes, material conveying pipes, automobile cover parts processing, etc.

4. Metal sheet processing, usually refers to cutting, bending, calendering, rummaging and other methods. Generally speaking, the process of using molds to complete various deformation processes is called sheet metal stamping process, and the process of forming sheets by hand or machinery is called sheet metal processing.

Company Information

King Siu Metal Products (Shenzhen) Ltd. is located in Longgang District, Shenzhen, at No.10, Pingxi South Road, Xinsheng Community.

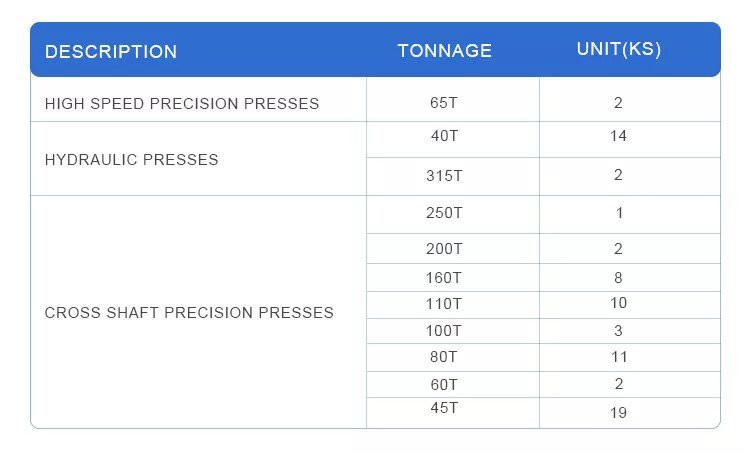

Our company was established in 1990, and now has a factory building of more than 8,000 square meters and more than 120 employees. Has passed the ISO 9001 and ISO 9002 quality system qualification certificates, and is also a high-tech enterprise in Longgang, Shenzhen.

King Siu Metal Products (Shenzhen) Ltd. is a high-tech enterprise integrating R&D, manufacturing, marketing and service. It is mainly engaged in hardware manufacturing, such as sheet metal, CNC, stamping, speaker nets, etc.

Our customers include SONY, PHILIPS, TOSHIBA, THOMSON, SHARP, ALTEC, OLYMPUS, CLARION, EASTECH, JVC, BOSE, HARMAN, CISCO, VTECH, YAMAHA, MARTION AUDIO and so on.

The products that have been produced mainly involve light rail bogies, light rail coupler systems, subway motor casings, subway motor stators, motor rotors, shafts, etc.; semiconductor equipment products mainly involve stainless steel vacuum chambers, brackets, amplifiers, audio equipment, etc.

Machinery equipment OEM (OEM) products mainly include all kinds of precision sheet metal processing, precision machining, surface treatment and various cabinets, equipment OEM assembly, involving security inspection equipment, industrial printing machines, coffee machines, air-conditioning brackets, etc.

FAQ

Packaging & Shipping

Packaging:

1. one piece in one carry bag

2. Suitable quantity to an export carton

3. No other packing accessories in regular

4. Customer required packing is available

Shipping: by air, sea, or express

Sample lead time: 5~7 days

Delivery time: about 25~30 days after order details and production confirmed.

Our Services

Good knowledge on different market can meet special requirements.

Real manufacturer with our own factory located in Longgang District, Shenzhen, China

Strong professional technical team ensure to produce the top quality products.

Special cost control system ensure to provide the most favorable price.

Rich experience on outdoor equipment.

Hot Tags: cutting and bending sheet metal, China cutting and bending sheet metal manufacturers, suppliers, factory, Laser Cutting Galvanized Steel, Cutting And Bending Sheet Metal, Laser Cut Copper Sheet, Cutting Curves in Sheet Metal