Stamped Sheet Metal is a highly versatile product that is widely used across various industries. The product is created by stamping or pressing sheet metal into different shapes, sizes, and thicknesses, depending on the desired end-use.

Our stamped sheet metal is made from premium quality materials, including stainless steel, aluminum, brass, and copper, which are sourced from reliable and reputable suppliers. This guarantees the durability, strength, and long-lasting quality of the product, ensuring that it delivers on its intended purpose.

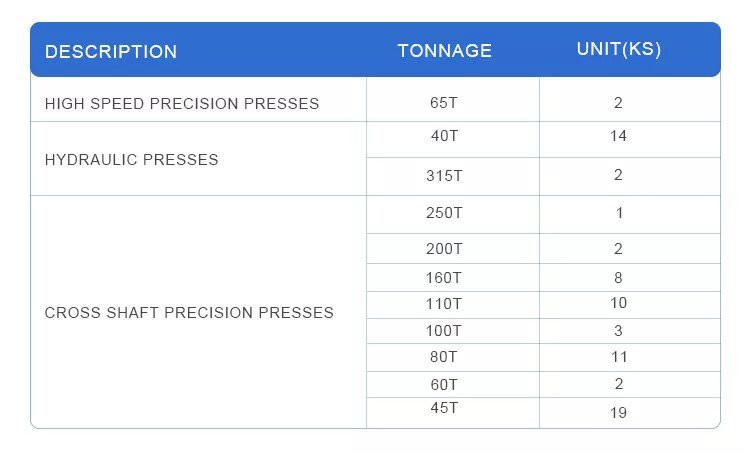

At our factory, we have highly skilled and experienced technicians who utilize state-of-the-art equipment and cutting-edge technology to create stamped sheet metal that meets industry standards and customer expectations. Our manufacturing process involves precision stamping, punching, and shaping of the sheet metal to deliver intricate and complex designs that cater to various applications, such as automotive, aerospace, construction, and electrical.

Our product range includes a variety of stamped sheet metal products, such as enclosures, brackets, electrical components, automotive parts, hardware, and much more. We can also customize our products based on customer requirements, including size, shape, material, and finish, enabling us to cater to every specific need.

One of the significant advantages of our stamped sheet metal is that it is lightweight, making it easy to transport, install, and handle. This reduces transportation costs and provides ease of use, making it an ideal material for various applications.

Our stamped sheet metal product has excellent corrosion resistance properties, which ensure it remains unaffected by environmental conditions, including moisture, heat, and cold. Additionally, it is non-toxic, making it ideal for various industrial and commercial applications.

Moreover, we offer competitive prices for our stamped sheet metal products to ensure affordability, which is beneficial to our customers' bottom line. We guarantee quality and fast delivery of our products, ensuring that our customers receive their stamped sheet metal on time and in excellent condition.

Overall, our stamped sheet metal product is an excellent choice for merchants who value quality, durability, and versatility. Our superior manufacturing process, premium quality materials, and competitive prices make us the preferred supplier of stamped sheet metal worldwide.

Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for stamped sheet metal |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

What are the advantages of stamped sheet metal?

(1) Stability. Stamping dies ensure the size and shape accuracy of metal stamping parts, and protect the surface of stamping parts during processing. In addition, the life of the die is generally long, so the quality of metal stamping is stable.

(2) The scope of application is large. Metal stamping can process parts with a large size range and complex shapes, such as stopwatches as small as clocks and watches, as large as car longitudinal beams, covering parts, etc., plus the cold deformation and hardening effect of materials during metal stamping, the strength and strength of metal stamping The stiffness is high.

(3) High efficiency. The production efficiency of metal stamping processing is high, and the operation is convenient, and it is easy to realize mechanization and automation. This is because metal stamping relies on dies and stamping equipment to complete the processing. The number of strokes of ordinary presses can reach dozens of times per minute, and high-speed pressure can reach hundreds or even thousands of times per minute. It is possible to get a stamped piece.

(4) Cost controllable. Metal stamping generally does not generate chips and scraps, consumes less materials, and does not require other heating equipment, so it is a material-saving and energy-saving processing method, so the cost of metal stamping parts can be well controlled.

Company Information

King Siu Metal Products (Shenzhen) Limited produces high quality metal horn mesh, aluminum oxide trim, audio CD, digital camera, laptop, aluminum shell, automotive metal parts, stamped sheet metal mainly. After years of development and business expansion through the IS09001 and ISO9002 quality systems, we provide comprehensive manufacturing processes, such as mold design, stamping, CNC machining, sandblasting, surface planting, oxidation, printing, etc., equipped with professional production machines and testing equipment.

FAQ

Our Services:

1. Good knowledge on different market can meet special requirements.

2. Real manufacturer with our own factory located in Longgang, Shenzhen, China.

3. Strong professional technical team ensure to produce the top quality products.

4. Special cost control system ensure to provide the most favorable price.

5. Rich experience on metal hardware product.

Why choose us?

- Our Metal Sheet Parts are resistant to corrosion, oxidation, and other forms of degradation.

- We implement the concept of "innovation leads the trend" to provide customers with more specialized services and personalized Stamped Sheet Metal, and look forward to our joint cooperation and development.

- Our Metal Sheet Parts are made with high-quality materials that are resistant to wear and tear.

- Our company develops rapidly, pays great attention to product quality, and establishes a production and management philosophy centered on quality and reputation.

- Our Metal Sheet Parts are made with materials that can withstand extreme temperatures and harsh environments.

- Based on the original products, our company continuously introduces new technologies and develops various new Stamped Sheet Metal to meet the needs of the market.

- We specialize in the manufacturing of complex and intricate Metal Sheet Parts.

- Our corporate vision is: those who can do well build are good and they are successful. And leading the industry and world-class is our strategic vision.

- Our Metal Sheet Parts are available in various shapes, sizes, and materials for customization.

- We have established a first-class efficiency, first-class service marketing team. Our strong technical force, high-quality and low-cost products, first-class marketing after-sales service is your best choice.

Hot Tags: stamped sheet metal, China stamped sheet metal manufacturers, suppliers, factory, Sheet Metal Digital Electronic Enclosure, Sheet Metal Shield Shell, Sheet Metal Temperature Sensor Housing, Precision Sheet Metal Parts, Sheet Metal Front Plate, Sheet Metal Battery Shrapnel