Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal medical equipment housing |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Processing method of Sheet metal medical equipment housing:

1. CNC bending machines, laser cutting machines and other equipment to form sheet metal processing for small batch production, high cost samples

2. The sheet material is processed on the press through dies and other sheet metal processing equipment, which is fast and low cost, but the cost of large molds is low, and the installation and replacement of fixed parts for mass production.

Sheet metal processing:

1. Cutting: blanking die, laser cutting, shearing, number of punching holes

2. Forming: number of punches, number of folds and metal dies used for forming

3. Other processing: riveting and tapping

4. Arc welding, resistance welding

5. Surface treatment: powder coating, electrophoresis, electroplating, etc.

Company Information

King Siu Metal Products (Shenzhen) Ltd. was established in 1990, located in Longgang District, Shenzhen City, with a factory area of 8000 square meters. It is a sheet metal processing manufacturer integrating production and mold manufacturing. The company's main products include the design and manufacture of sheet metal products, automation equipment rack sheet metal, power supply equipment cabinets, medical equipment shell consoles, etc., serving terminals in the fields of electric power, medical care, communications, industry, rail transit, finance, and new energy product.

Our main goal is to pursue excellent quality, provide customers with excellent sheet metal products, and strive to become an excellent sheet metal manufacturer. For a long time, the company has been following the policy of being customer-oriented and making continuous improvements so that customers can obtain more professional and cost-effective solutions. Relying on the company's experience and resources, coupled with careful production, sales and other links, the products strive for perfect quality, and are committed to becoming an excellent OEM/ODM sheet metal manufacturer in the market.

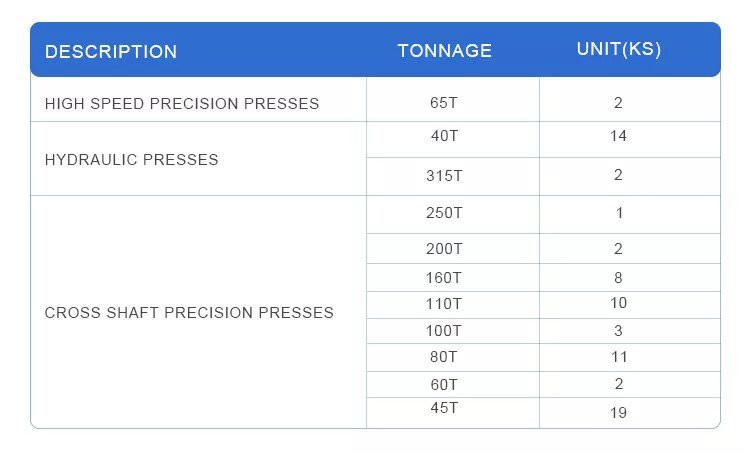

With advanced development and production equipment, the company's existing main production equipment includes: CNC punching machines, CNC bending machines, automatic riveting machines, argon arc welding machines and collision welding machines. The company provides customers with special solutions in sheet metal technology and parts matching. In addition, the annual R&D investment is 10% of the profit. Through advanced equipment and technology, the company always grasps the latest market trends of sheet metal products and manufactures novel sheet metal products for customers.

Based on ISO9001 "Quality Management System Requirements", we study the management mode of excellent enterprises, combine many creative suggestions with specific work, determine the company's quality policy and goals, formulate a series of standards and management procedures, establish and We have perfected a complete company quality management system to ensure that everyone has rules to follow in their work, and the company is responsible for everything.

FAQ

When did your factory established?

Since 1990.

Do you have QC department?

Yes,we have 12 QC persons.

Do you have booth in shows?

Yes, we have booth in every globalshop and Euroshop.

Hot Tags: sheet metal medical equipment housing, China sheet metal medical equipment housing manufacturers, suppliers, factory, Sheet Metal C shaped Bending Parts, Sheet Metal Extrusions, Sheet Metal Precision Bending Parts, Sheet Metal Motor Housing, Sheet Metal Panel, Sheet Metal Battery Hardware