Introduction:

Sheet Metal Front Plate is one of the most popular products offered by my company. We are a leading manufacturer of sheet metal products in China, and we offer a wide range of sheet metal fabrication services to our clients.

Sheet Metal Front Plate is a product that is meant for merchants who want to use it in a wide variety of applications. The product is highly versatile and can be used in a number of industries, including automotive, construction, and industrial manufacturing.

Features:

The Sheet Metal Front Plate is made of high-quality materials and is designed to be highly durable and long-lasting. The product is made of sheet metal, which makes it highly resistant to corrosion and wear and tear. The sheet metal construction also makes it highly resistant to impact and damage.

The product is available in a range of sizes and thicknesses to suit the needs of different applications. This means that merchants can choose from a variety of options that best suits their specific needs.

Uses:

The Sheet Metal Front Plate can be used in a variety of applications, including automotive, construction, and industrial manufacturing. In the automotive industry, it can be used as a front plate on vehicles. It can also be used in the construction industry as a roofing material, siding, or as a foundation for buildings.

In the industrial manufacturing industry, it can be used as a protective covering for machinery or as a component of production equipment. Overall, the product is highly versatile and can be used in a wide range of applications.

Advantages:

There are several advantages to using the Sheet Metal Front Plate. Firstly, it is highly durable and long-lasting, which means that it can withstand harsh environmental conditions and last for a long time. This makes it a cost-effective solution for merchants who want to invest in a product that will last for a long time.

Secondly, the product is highly customizable, which means that it can be tailored to suit the specific needs of different industries and applications. This means that merchants can choose from a range of sizes, thicknesses, and coatings to best suit their specific requirements.

Finally, the product is highly versatile, which means that it can be used in a wide range of applications. This makes it a highly valuable product for merchants who want to invest in a product that can be used in multiple industries and applications.

Conclusion:

Overall, the Sheet Metal Front Plate is a highly versatile and durable product that is ideal for merchants who want to invest in a product that will last for a long time. The product is highly customizable and can be tailored to suit the specific needs of different industries and applications. With all of these advantages, it is no wonder that the Sheet Metal Front Plate is such a popular product among merchants outside of China.

Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal front plate |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Sheet metal front plate is an essential component in computer cases, mobile phones and MP3 players. As sheet metal is widely used, sheet metal design has become a very important part of the product development process. Mechanical engineers must master sheet metal design skills, so that the designed sheet metal can not only meet the requirements of product function and appearance, but also make the stamping die manufacturing simple and low cost.

Generally speaking, the basic equipment of sheet metal process includes plate shears, CNC punch/laser, plasma, water jet cutting machine, bending machine and various auxiliary equipment such as uncoiler, straightener, deburring machine, spot welding machine. Generally speaking, the four most important steps in sheet metal working are cutting, stamping/cutting, folding, welding, surface treatment, etc.

Sheet metal front plate is plastic deformed by hand or die stamping to form the desired shape and size, in addition, more complex parts can be formed by welding or light machining, such as chimneys, tin stoves and car casings commonly used in homes are all sheet metal parts.

Company Information

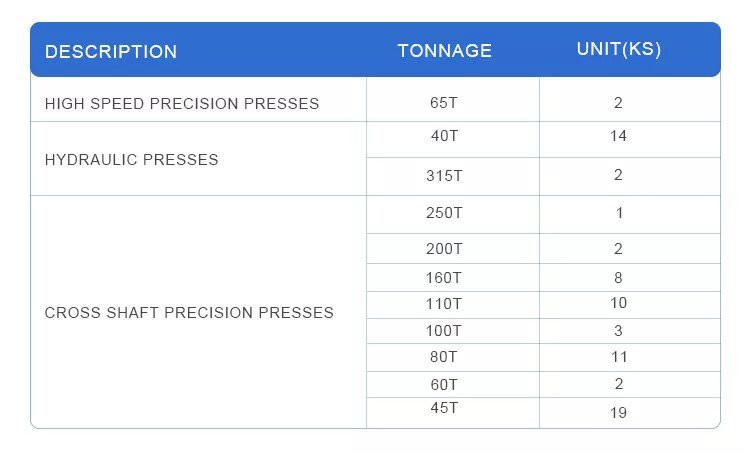

King Siu Metal Products (Shenzhen) Limited was established in 1990, located in Pingsouthwest Road, Xinsheng Community, Longgang District, Shenzhen, China.The factory covers an area of more than 8,000 square meters, mainly producing hardware accessories such as audio machine shell, horn net and heat sink. Has passed ISO9001 and ISO9002, quality certification system. By professional production personnel to provide production process, including mold design, mold manufacturing, stamping forming, welding, pretreatment, oil spray screen printing, equipped with advanced production equipment!

FAQ

Is the sample available?

Yes, we are providing free of samples are available for you to check the quality once confirmed after 1~2day.

Is there the products tested before shipping?

Yes, of course. All of our conveyor belt we all will has been 100% QC before shipping. We test every batch every day.

Are you manufacturer or trade company?

We are manufacturer and there are 3 family factories in Hongkong, Shenzhen.

Why choose us?

- Our Metal Sheet Parts are made with precision CNC machinery to ensure accuracy and consistency.

- We sincerely hope to have the opportunity to meet with you and see how we can help you further your own business.

- Our Metal Sheet Parts are resistant to corrosion, oxidation, and other forms of degradation.

- In the new century, our company is constantly developing and innovating, changing the management ideas and methods, and connecting with the international market, so that the enterprise will continue to develop, grow and prosper.

- Our skilled technicians use the latest technology to create Metal Sheet Parts of exceptional quality.

- In line with the 'pursuit of excellence, continuous innovation' purpose, we sincerely treat new and old customers.

- We offer a comprehensive range of Metal Sheet Parts to meet our customers' unique requirements.

- We constantly improve the added value of technological innovation, marketing services, and corporate culture in our products.

- We have a strong commitment to quality and continually strive to improve our Metal Sheet Parts.

- We determine the core of development as improving the quality of our Sheet Metal Front Plate, and implement the strategy of creating famous brand from grasping quality.

Hot Tags: sheet metal front plate, China sheet metal front plate manufacturers, suppliers, factory, Sheet Metal Aluminum Plate, Sheet Metal C shaped Bending Parts, Sheet Metal Stainless Steel Bending Parts, Sheet Metal Shield, Sheet Metal Battery Shrapnel, Sheet Metal L shaped Bending Parts