Introduction:

We are a professional manufacturer based in China who specializes in producing precision sheet metal bending parts. Our company is committed to offering high-quality and durable products that meet the demands of clients from all over the world. We understand the needs of our clients and use modern design and manufacturing techniques to meet even the most challenging demands.

Why choose our sheet metal precision bending parts?

1. High-quality materials

Our sheet metal bending parts are made from high-quality materials that are carefully selected before production. We use only the best materials, including stainless steel, copper, aluminum, and other alloys that meet international standards. We are committed to ensuring that our raw materials are of the utmost quality to guarantee durability and longevity.

2. Precision bending

Our sheet metal bending parts are manufactured using high-precision CNC machines to ensure exceptional accuracy and consistency. Our skilled technicians are dedicated to providing precise bending and forming, ensuring that the product dimensions are uniform and meet customer specifications. Our attention to detail is unparalleled, and we strive to provide faultless products.

3. Customization options

We understand that every client is unique, with different needs and specifications. As such, our company is committed to providing customized solutions for each client's precise needs. Our team of experts works with clients to deliver tailor-made solutions, ensuring that each client's unique requirements are met satisfactorily. We also offer a wide range of finishes, including powder coating, anodizing, and common finishes, to meet each client's specific needs.

4. Expertise in design

Our team of experienced engineers uses the latest design tools to design our sheet metal bending parts. We work closely with clients to ensure we deliver products that meet their expectations. Our design capabilities are top-notch, and we are committed to helping clients ensure that their products are of top-quality.

5. Competitive pricing

We understand that clients are continually seeking affordable solutions without sacrificing quality. As such, we strive to maintain competitive pricing without compromising on the quality of our products. Our company has adopted an efficient management system, which provides cost-effective and streamlined solutions for our clients. This way, we can offer excellent products at competitive prices!

Conclusion:

Our sheet metal precision bending parts are a great choice for merchants seeking high-quality and customized solutions at competitive prices. From precision bending to design expertise, we are committed to providing exceptional products that match and exceed our clients' specifications. With our skilled technicians, cutting-edge equipment, and premium materials, we are confident that we can meet your exacting requirements. Choose us, and you will have a reliable partner in manufacturing!

Product Specification

Material | Metals like stainless steel, brass, bronze, copper, hardened metals, precious metals, etc. |

Surface Treatment | In response to your inquiry |

Processing | Drilling, etching, milling, turning, welding, rapid prototyping, chemical processing, laser processing, broaching, etc. |

Certificate | ISO 9001, SGS, material certificate |

Drawing Format | CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Color | Customize |

Custom | Customized according to drawings, customized according to samples for Sheet metal precision bending parts |

Use industry | Other industries, such as the ship, fastener, and outdoor ones |

Merchandise Description

Bending is a crucial step in the manufacturing of sheet metal components made of stainless steel. The so-called bending process involves stamping the material under pressure to deform it into a specific angle and curvature. V-bending, Z-bending, and isobaric bending are all frequently utilized bending techniques. The most crucial aspect of bending is to pay attention to the bending gap, bending height, bending radius, and bending direction. This page was bent into the shape desired by previous clients. There are some challenges with bending stainless steel. 301 and 304 stainless steel are the two types of stainless steel that are typically bent.

The most widely used stainless steel is 304, but 301 stainless steel can also be bent more effectively due to its good ductility.

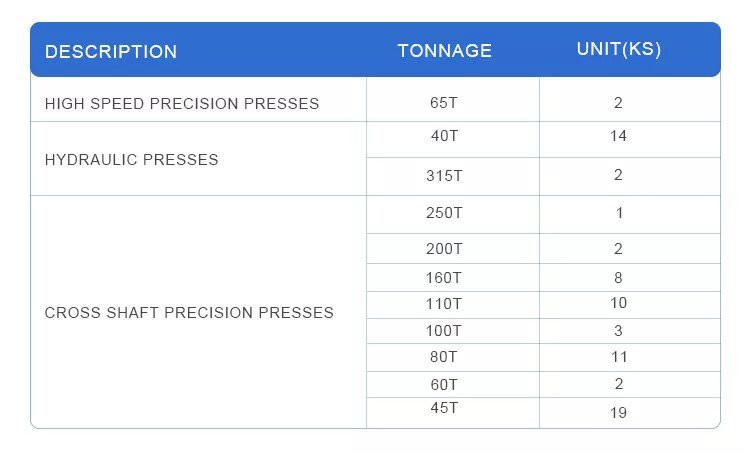

King Siu Metal Product (Shenzhen) Limited is a manufacturer with considerable experience in the field. The company has produced a variety of bespoke products, sheet metal components, machined parts, 3D printed parts, and plastic parts for clients. We have enough manufacturing capacity, select the best materials and processes based on customer needs, and use the best processing techniques to create goods of the highest quality.

Advantage In Production

1. Flexibility is good

In combination with CAD/CAM technology, the CNC bending machine can cut plates of any form and size, and is particularly well suited for cutting multi-variety, small-batch, and complex-shaped items. It also has exceptional flexibility after processing and doesn't require tools or molds.

2. High processing speed

Bending cutting is non-contact processing that has none of the negative effects of mechanical blanking, wear on the tools and molds, and mechanical blanking when blanking is overlapping. The workpieces are arranged closely, which can save 20% to 30% on materials, and it is one-time forming without cutting.

3. Extreme precision

Without rounded corners or mechanical cutting, the curved cutting incision is smoother and thinner. Small amounts of thermal stress, thermal deformation, and heat-affected zone exist.

FAQ

1. When will I receive samples?

It typically takes 10 to 20 days, depending on the particulars of your project.

2. What if I'm not entirely happy with the parts I get?

We promise to adhere to your specifications about surface treatment, material, workmanship, acceptable tolerances, etc. Any adjustments that are either not possible or not wanted will be disclosed to you in advance. If you have stringent requirements or are still uneasy, we will promptly offer you samples prior to shipment so that you can confirm that it truly satisfies your needs.

3. If you gain something, would my drawing be revealed?

No, we take great care to protect the privacy of our customers' drawings by signing NDAs.

Is also welcomed if necessary.

Why choose us?

- We are committed to providing our customers with the best Metal Sheet Parts at cost-effective prices.

- Our company always emphasizes that employees are the fundamental cornerstone of enterprise development, and we should always pay attention to the common growth of employees and enterprises, to strengthen confidence, gather people's hearts, warm hearts, build one heart, and always maintain the overall development and vitality of the workforce.

- Our Metal Sheet Parts are manufactured using environmentally friendly methods.

- The company firmly believes that customer satisfaction is the driving force of the enterprise. "Win-win with customers" is our philosophy that we will always adhere to. Therefore, we will, as always, launch better products and more considerate services.

- We are constantly innovating to offer Metal Sheet Parts that meet our customers' evolving needs.

- We will supply high-quality solutions and fantastic companies at aggressive charges.

- Our Metal Sheet Parts are made with materials that are safe for use in various applications.

- We follow the trend and constantly seek new breakthroughs in Sheet Metal Precision Bending Parts, quality, service and operation mode, sales channels and sales methods.

- We offer a broad range of Metal Sheet Parts to cater to our customers' diverse requirements.

- Our company is an old technology-based brand enterprise with design, research and development, and manufacturing Sheet Metal Precision Bending Parts.

Hot Tags: sheet metal precision bending parts, China sheet metal precision bending parts manufacturers, suppliers, factory, Sheet Metal Housing Parts, Sheet Metal Base Plate, Sheet Metal Camera Housing, Sheet Metal Battery Shrapnel, Sheet Metal Front Plate, Sheet Metal Bracket