Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal shield shell |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Sheet metal shield shell has the following features:

(1) Stability, stainless steel stamping parts are punched out of raw material stainless steel, and its corrosion resistance can ensure stability and no deformation in multiple environments (or long-term normal conditions), which is for the precision structural parts of ATM is extremely important;

(2) Aesthetics, after being polished, the workpiece has a good bright effect, looks beautiful and atmospheric, and can be used as an appearance part of the product;

(3) Weldability, good welding performance can meet the needs of diverse scarfing of internal structural parts and assembly of finished products, and excellent processing performance;

(4) Iterative, customized mass production, flexible update of product functions, and effective cost control;

(5) High precision, our company has many years of experience in the production of high-end precision stamping parts, and has strict requirements on product precision (control error range ≤ 0.1mm);

Features of Sheet Metal Parts

Sheet metal parts have the characteristics of being thin and easy to form, and can be formed into parts of various shapes. With the application of welding, assembly, riveting and other processes, it is possible for the product to realize multiple structures. At the same time, these characteristics also cause sheet metal parts to be more or less deformed in different degrees during the processing process, such as bending deformation, torsional deformation, concave-convex deformation, etc. These deformations change the size or shape of the entire component, causing quality problems. However, the production process of sheet metal parts has its own inherent rules. For the same type of products, according to the existing equipment and manpower, the order of processing can be flexibly adjusted to give a reasonable processing process.

Company Information

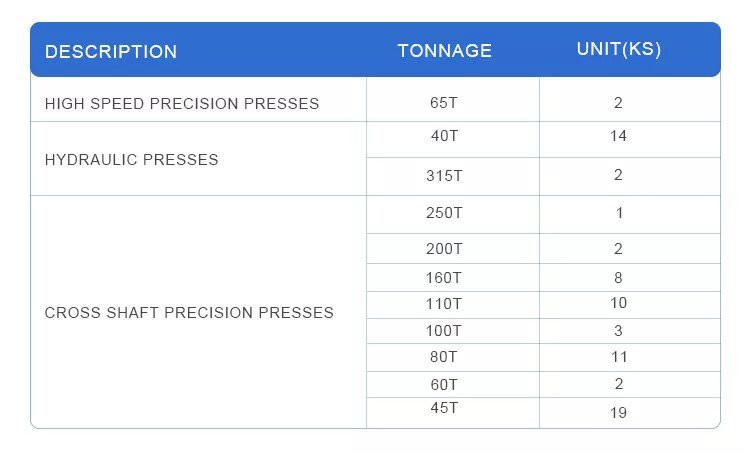

King Siu Metal Products (Shenzhen) Limited produces high quality metal horn mesh, aluminum oxide trim, audio CD, digital camera, laptop, aluminum shell, Sheet metal shield shell mainly. After years of development and business expansion through the IS09001 and ISO9002 quality systems, we provide comprehensive manufacturing processes, such as mold design, stamping, CNC machining, sandblasting, surface planting, oxidation, printing, etc., equipped with professional production machines and testing equipment.

FAQ

Q: Do you provide sample ? Is it free?

A: If the sample value is low, we will provide free samples, and the freight will be borne by your company. But for some high-value samples, we need to charge sample fees.

Q: What is your term of payment?

A: 50% down payment before producing and 50% balance payment before shipping.

Q: Which payment form you can accept?

A: T/T, Western Union, PayPal etc. We accept any convenient and swift payment term.

Hot Tags: sheet metal shield shell, China sheet metal shield shell manufacturers, suppliers, factory, Sheet Metal Camera Housing, Precision Sheet Metal Parts, Sheet Metal Battery Shrapnel, Sheet Metal Temperature Sensor Housing, Sheet Metal Housing Parts, Sheet Metal Motor Housing