Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal stainless steel shield |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Sheet metal stainless steel shield bending stamping processing principle:

Fix the upper and lower molds on the upper and lower worktables of the folding bed respectively, and use hydraulic transmission or servo to drive the relative movement of the worktables, combined with the shape of the upper and lower molds, so as to realize the bending and forming of the plate. Generally, it is divided into upper and lower molds. The basic principle of the bending process sequence is moving type and down moving type: bending from the inside to the outside and bending from small to large. The special shape is bent first, and then the general shape is bent. After the previous process is formed, it will not affect the subsequent process.

Common uses of bending/stamping equipment:

Forming, drawing convex hull, pressing foot, pressing line, embossing characters, rivet, riveting electrostatic guide rail, pressing ground symbol drawing hole, riveting, pressing flat, pressing triangle reinforcement, etc.

Processing accuracy of folding bed:

One fold: +/-0.1mm

20% off: +/- 0.2mm

More than 20% off: +/- 0.3mm

Company Information

King Siu Metal Products (Shenzhen) Limited's main business scope is manufacturing and processing Sheet metal stainless steel shield, Products are well received by domestic and foreign famous electrical manufacturers such as SONY, PHILIPS, TOSHIBA, THOMSON, SHARP, ALTEC, OLYMPUS, CLARION, EASTECH, JVC, BOSE, HARMAN, CISCO, VTECH, YAMAHA, MARTION AUDIO and other trust.

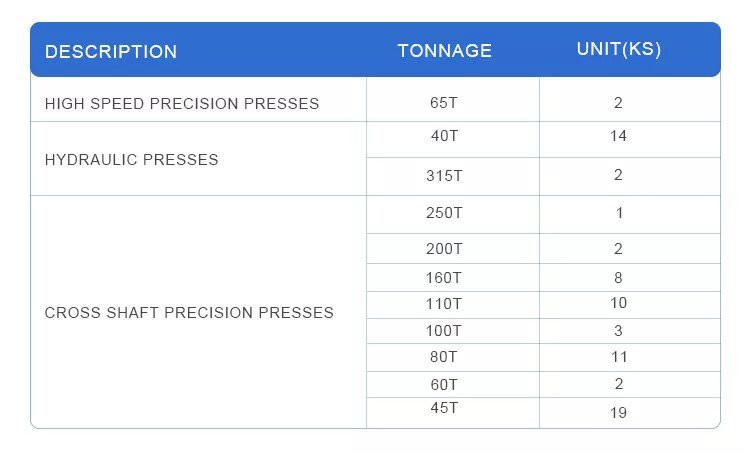

Has a range of stamping and forming equipment for in-house production, and experienced engineers to evaluate and design standard and progressive tooling.

We can do laser cutting, bending, welding, threading and chamfering, deburring, riveting and other processes, and have a complete supply chain for a variety of surface treatments, so we have the ability to meet customer requirements for components and assemblies need.

The Solutions We Provide

Rice processing

Customized meal processing services for medium to large volume orders.

Tube processing

Tube processing services for small to large volume orders.

Laser cutting

Precision laser cutting and CNC bending manufacturing services.

Injection molding

Manufacturing and assembly services for small to high volume orders.

Stamping

Stamping and progressive tooling services for medium to high volume orders.

Assembly

Contract manufacturing services for finished assembly.

FAQ

Q: When can I get the price?

A: Usually we quote within 24 hours after we get your inquiry.

Q: What’s your MOQ?

A: We can discuss the minimum order quantity according to the size of the product, the processing method and the specific situation of the customer.

Q: How long is your delivery time?

A: We determine the delivery time according to the different processes of the products. The general delivery time is 10-15 days, 20-25 days, 30-35 days and 40-45 days after receiving the order confirmation.

Hot Tags: sheet metal stainless steel shield, China sheet metal stainless steel shield manufacturers, suppliers, factory, Sheet Metal Communication Equipment Shell, Sheet Metal Processing Board, Sheet Metal Motor Housing, Sheet Metal Extrusions, Sheet Metal Back Panel, Sheet Metal Bending Parts