Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal aluminum shield |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Sheet metal aluminum shield processing principle:

Laser (laser) cutting is powered by electronic discharge, using mixed gases such as He, N2, and CO2 as the excitation medium, and using mirror groups to focus and generate laser beams to cut materials. Driven by a program-controlled servo motor, The cutting head moves according to the predetermined route to cut workpieces of various shapes.

Common uses of laser machines:

Cutting, cutting shape, secondary cutting, cutting line, cutting special-shaped hole.

The processing accuracy of the laser machine:

+/-0.1mm

Spray Processing

Spraying processing is after the surface treatment, and the product is sprayed.

When spraying, the workpiece is first hung on the assembly line, and the dust stuck on the surface is blown off with the air pipe.

Enter the spraying area to spray, after spraying, enter the drying area along the assembly line, and finally remove the sprayed workpiece from the assembly line.

The main spraying methods are manual spraying and automatic spraying.

Provide plastic spraying process, the surface of the finished product is very good, and meet the requirements of environmental protection, the surface adhesion is strong, not easy to burn, can protect the metal surface for a long time, the service life is much longer than the finished product of spray paint, but the color is less optional .

Silk Screen Processing

Screen printing is to print corresponding text, characters, patterns, logos, etc. on sheet metal products through screen printing, making sheet metal products more distinctive.

The screen printing method is flexible and diverse, and can be printed on multiple planes. The adhesion is strong, the screen printing content is not easy to fall off, and the gloss is long-lasting, which can be maintained outdoors for a long time.

However, it is mainly printed on a flat surface, and cannot be printed on a curved/concave-convex surface. Support CAD/CRAWDRAW to draw silk screen files.

At the same time, for screen printing, one screen has one color, and the number of colors will affect the number of screens and the cost of screen printing. Therefore, it is recommended to choose a single color or design as few colors as possible to control the cost of screen printing.

Company Information

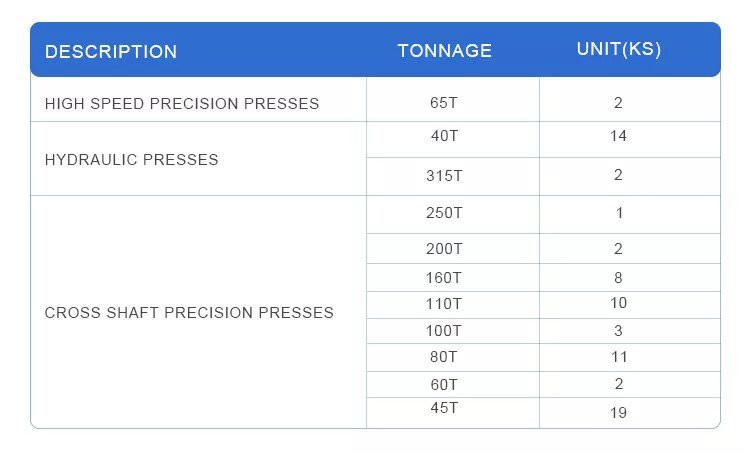

King Siu Metal Products (Shenzhen) Limited produces high quality metal horn mesh, aluminum oxide trim, audio CD, digital camera, laptop, aluminum shell, automotive metal parts mainly. After years of development and business expansion through the IS09001 and ISO9002 quality systems, we provide comprehensive manufacturing processes, such as mold design, stamping, CNC machining, sandblasting, surface planting, oxidation, printing, Sheet metal aluminum shield etc., equipped with professional production machines and testing equipment.

FAQ

Q: How many packaging do you have?

A: We currently have five packages, including PE bags, pearl cotton, cartoon boxes, color boxes and white boxes.

Q: Can you do our own packaging?

A: Yes, you just provide the package design and we will produce what you want. We also have the professional designer can help you do the packaging design.

Q: How many different types of products your company manufactures?

A: Now we have more than 1000 products. We have strong OEM advantages. As long as you give us the actual samples or your drawings you want, we will make them for you.

Hot Tags: sheet metal aluminum shield, China sheet metal aluminum shield manufacturers, suppliers, factory, Sheet Metal Bending Parts, Sheet Metal Front Plate, Sheet Metal Housing Parts, Sheet Metal Medical Equipment Housing, Stamping Sheet Metal Parts, Sheet Metal Base Plate