Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal digital electronic enclosure |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

The material of Sheet metal digital electronic enclosure is electrolytic plate (SECC):

It is rolled by the cold tandem rolling unit and then annealed by the CAPL unit, then enters the electro-galvanizing unit, and after the surface is cleaned and electroplated, it can be treated with phosphating, passivation, oiling, anti-fingerprint and alloying according to different purposes. The product.

Processing Technology:

Cutting

The shape and hole of the product can be punched out at the same time, and at the same time, the size requirements of the product and the height of the product burr can be guaranteed.

Punching

Punching according to the product process structure, while ensuring the life and precision of the mold.

L song

Bending according to the product structure, mold bending can ensure the product size requirements and the stability in the production process.

Auxiliary process

Knife grinding, degreasing, nesting nails, silver coating, etc., to make the parts look beautiful and anti-corrosion. Anti-rust section.

Cleaning packaging

The fully automatic ionized water spray cleaning line and the 7-tank automatic ultrasonic cleaning machine rely on electrolyzed water to decompose into anions and cations, and then use the "activation" of active particles in the ions to remove stains on the surface of objects.

Company Information

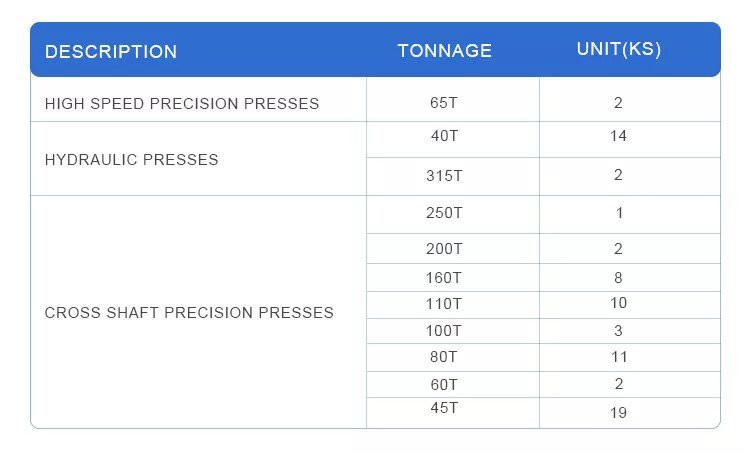

King Siu Metal Products (Shenzhen) Limited not only introduced high-performance punching machines from Germany and Japan, but also introduced 5 automatic production lines to ensure the performance and quality of stamping products, and at the same time provide customers with various types of high-difficulty products faster. , High-precision stamping products, the precision has reached 0.05mm, and the punching area and punching thickness are also at a high level in the industry.

In order to provide customers with diversified services, it is equipped with sophisticated assembly and packaging production lines to truly achieve "integrated services", and introduces German ion water spray cleaning machines and ultrasonic cleaning machines to provide customers with packaging services. The introduction of ATM's core technology movement assembly and the precision fitting assembly of various large cabinets has expanded the customer's production capacity and equipment.

FAQ

What about the lead time for mass production?

15-20 working days for mass production. It depends on your quantity,and we will try our best to meet your needs.

How can I place an order?

You can contact any of our sales person for an order. Please provide the details of your requirements as clear as possible. So we can send you the offer at the first time.

For designing or further discussion, it is better to contact us with Skype, TradeManger or QQ or WhatsApp or other instant ways, in case of any delays.

What is your terms of delivery?

We accept EXW, FOB, CFR, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

Hot Tags: sheet metal digital electronic enclosure, China sheet metal digital electronic enclosure manufacturers, suppliers, factory, Sheet Metal Stainless Steel Shield, Sheet Metal Electromagnetic Shield, Stamped Sheet Metal, Sheet Metal Temperature Sensor Housing, Sheet Metal Special shaped Bending Parts, Sheet Metal Motor Housing