Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Stamping bracket |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

The deformation process of the sheet during stamping bracket blanking

Deformation process:

When the die clearance is normal, the blanking process of metal materials can be divided into three stages:

1) Elastic deformation stage

Sheet metal undergoes deformations such as elastic compression, bending and stretching. The material deforms or changes in size when it is subjected to an external force, and the deformation that can be restored is called elastic deformation.

2) Plastic deformation stage

The stress of the sheet metal reaches the yield limit, and the sheet metal begins to produce plastic shear deformation. It refers to that part of the deformation of the material that is produced under the action of an external force and cannot be recovered after the external force is removed.

3) Fracture separation stage

The formed crack extends into the material along the direction of the maximum strain rate and develops in a wedge shape

Forming process: it is to make the sheet material plastically deform under the condition of not being damaged, and make a workpiece of the required shape and size.

Forming process: bending, rounding, twisting, deep drawing, thinning and deep drawing, flanging (hole flanging, outer edge flanging), shrinking, flaring, undulation, curling, expanding, spinning, shaping , leveling, embossing, extrusion (forward extrusion, reverse extrusion, compound extrusion).

Company Information

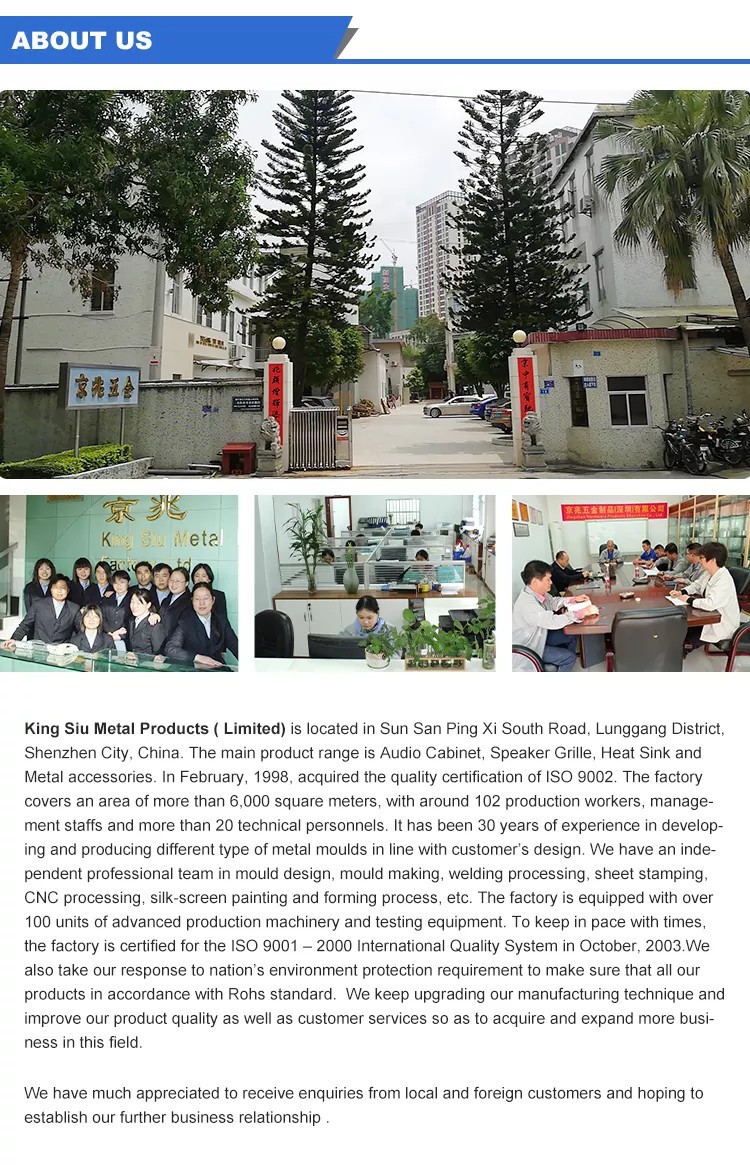

King Siu Metal Products (Shenzhen) Limited OEM supporting business

Welded assembly

Already have rich manufacturing capacity of four-door body front and rear covers and front and rear floor assemblies, have rich experience in spot welding, projection welding, stud welding, laser welding and other welding processes of body parts, master SPR riveting, SPS automatic Piercing screw riveting, Clinch riveting and robotic automatic gluing and other connection process capabilities.

New energy products

In the field of new energy vehicles, SSDT pays close attention to the new needs and needs of customers, develops synchronously with customers, actively promotes technology research and accumulation in the field of new energy, masters the core technologies from stamping, welding, coating to sealing, and has mass production technical strength. Products include lightweight battery cases and metal bipolar plates for hydrogen fuel cells.

FAQ

Visting factory is allowed or not?

Yes, we welcome customers visiting our factory. Our factory is located Shenzhen city, Guangdong province, China mainland.

Packaging & Shipping?

Packaging:

1. One piece in one carry bag

2. Suitable quantity to an export carton

3. No other packing accessories in regular

4. Customer required packing is available

Hot Tags: stamping bracket, China stamping bracket manufacturers, suppliers, factory, Stamped Panel, Stamped Stainless Steel Drawings, Stamping Surface Cover, Stamping And Drawing Parts, Stamped Housing Parts, Stamped Motor Housing