Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Stamping battery shrapnel |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Stamping process of stamping parts:

1) Shape and angle of Stamping battery shrapnel: The shape design of stamping parts should be as simple and symmetrical as possible to minimize waste during layout. The corners of blanking parts should avoid sharp corners, and appropriate rounded parts should be provided.

2) Minimum hole diameter for punching

The structural size of the stamping battery shrapnel (such as pore size, hole distance, etc.) must take into account the thickness of the material.

3) Minimum hole spacing and hole edge distance

The distance between the holes of the stamping battery shrapnel and between the holes and the edge should not be too small.

Stamping processability of bending parts:

1) When the material is bent, when the bending fillet exceeds the ultimate strength of the material, cracks and breaks will occur, and too small bending fillet radius should be avoided.

2) It is best not to set the R angle greater than 1.5 times the thickness of the material itself. Because the R angle is too large, its rebound is also very large after bending.

3) The bending height of the bending part should not be too long, and H should not be too small, especially when the material t>2mm is too small (remember), it will make bending difficult and it is difficult to obtain parts with accurate shapes.

4) Try not to design the bending line of the bending part in the place where the width changes suddenly.

Company Information

OEM supporting business

Aluminum products

King Siu Metal Products (Shenzhen) Limited already possesses arc welding of aluminum alloy body structure parts, aluminum alloy resistance spot welding, aluminum alloy friction stir welding, UV curing adhesive, synchronous development and integrated development capabilities, extrusion parts secondary molding processing development capabilities, The main products include: aluminum alloy CCB, aluminum alloy front and rear bumpers, aluminum alloy battery tray, chassis structural parts, body structural parts, etc.

Mold tooling business

Cover Mold

King Siu Metal Products(Shenzhen) Limited has the ability to develop, design, manufacture and debug large-scale body panel molds and inspection tools. The main products include fenders, side panels, four doors, front and rear covers, roof covers, etc.

FAQ

Our Services?

Good knowledge on different market can meet special requirements.

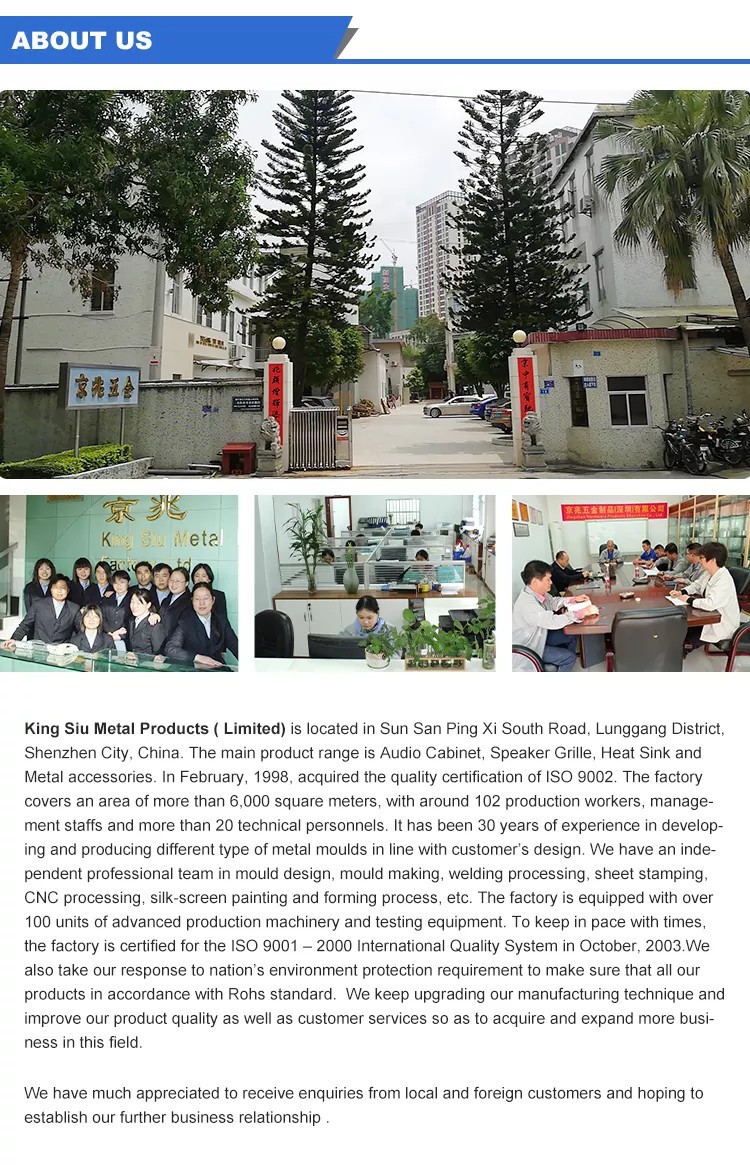

Real manufacturer with our own factory located in Longgang District, Shenzhen, China.

Strong professional technical team ensure to produce the top quality products.

Special cost control system ensure to provide the most favorable price.

Rich experience on outdoor equipment.

Do you provide sample?

Yes, we provide sample and the sample cost will be reback to you when confirm the order.

What's your products?

Cnc, Speaker grill mesh, stamping. etc.

Hot Tags: stamping battery shrapnel, China stamping battery shrapnel manufacturers, suppliers, factory, Stamping And Drawing Parts, Stamping Temperature Sensor Housing, Stamping Surface Cover, Stamping Precision Bending Parts, Stamped Front Plate, Stamped Camera Housing