Introducing the Stamping Surface Cover – A Revolutionary Solution for Your Manufacturing Needs

As a manufacturer, we understand the importance of protecting your products during the manufacturing process. That's why we've created the Stamping Surface Cover, a revolutionary solution designed to help you protect your products and improve the overall efficiency of your manufacturing process.

Our Stamping Surface Cover is made from high-quality materials, ensuring that your products are protected from damage and contamination during the manufacturing process. The cover is designed to fit a wide range of stamping surfaces, making it a versatile solution suitable for use across a range of industries.

One of the standout features of our Stamping Surface Cover is its ability to withstand high temperatures. Unlike other covers on the market, our product can withstand temperatures of up to 300 degrees Celsius, making it perfect for use in industries such as automotive, aerospace, and electronics.

In addition to its heat-resistant properties, the Stamping Surface Cover is also incredibly durable. The material used in the construction of the cover is abrasion and tear-resistant, meaning that it can withstand repeated use without deteriorating or needing replacement.

Another important feature of the Stamping Surface Cover is its ease of use. The cover is designed to be lightweight and easy to handle, allowing for quick and easy installation and removal. This feature is particularly important for manufacturers who need to frequently change their stamping surfaces, as it helps to reduce downtime and increase productivity.

In terms of cost-effectiveness, the Stamping Surface Cover is an excellent choice for manufacturers. The cover is reusable and can be cleaned easily, reducing the need for frequent replacements and lowering overall production costs. Additionally, the cover's ability to protect products from damage and contamination ensures that the manufacturing process is more efficient, thereby reducing costs and increasing profits.

Overall, the Stamping Surface Cover is an excellent solution for manufacturers looking to improve the efficiency and effectiveness of their manufacturing processes. Its heat-resistant properties, durability, ease of use, and cost-effectiveness make it a standout product in its category. If you're looking for a reliable and efficient way to protect your products during the manufacturing process, look no further than the Stamping Surface Cover.

Product Specification

Material | Metal: mild steel, aluminum, stainless steel, etc. |

Surface Treatment | Powder coating, (regular and hard) anodizing, electropolishing and polishing, electroplating, sandblasting, heat treatment, passivation, black oxide, brushed, laser engraving |

Processing | Punching, blanking, forming, bending, welding, etc. |

Certificate | ISO 9001, SGS, material certificate |

Drawing Format | CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Color | Customize |

Use industry | Customized according to drawings, customized according to samples for stamping surface cover |

Custom | Wide range of applications |

Production Advantage

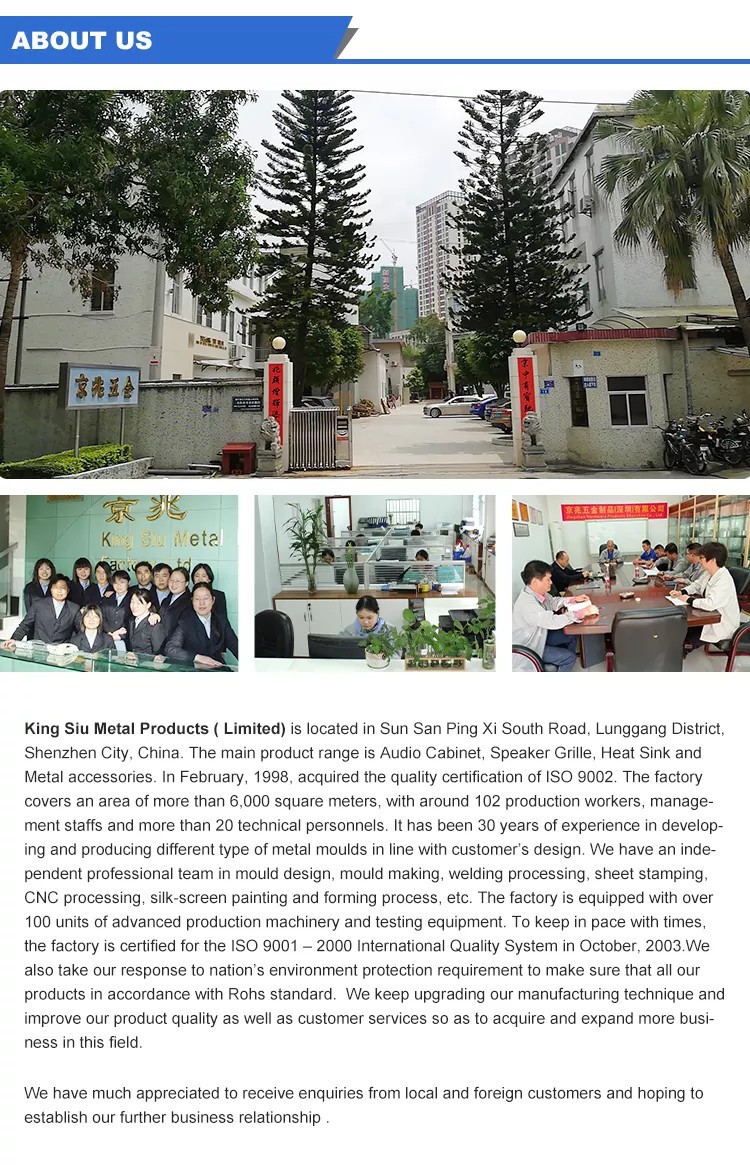

King Siu Metal Product (Shenzhen) Limited is a precision engineered manufacturer specializing in high quality machined components in a variety of materials utilizing the latest in CNC Turning, CNC Milling, Multi-Axis Machining, Sheet Metal Fabrication, Forming, Laser Cutting and bending techniques. With extensive experience in many industries, we are proud to work closely with our customers to improve their products.

Our company manufactures a wide variety of parts for many different industries. Such as aerospace, construction, automotive, commercial, medical, optical and marine industries, etc.

We have an experienced engineering team with ISO9001/ISO13485/AS9000/IATF16949 quality system and ERP/MES system, which is adaptable enough to meet the needs from one-off prototype to mass production. Our dedicated Planning and Estimating Team can assess and price all your needs in a timely manner. Always based on perfect quality, it is well received by foreign businessmen.

We sincerely welcome you and look forward to cooperating with you to create a better future.

Process

1. Inquiry (quantity + demand + drawings)

2. We quote for you

3. In the negotiation stage, you can put forward your ideas and requirements

Place order by T/T 30% deposit

4. We will arrange production for your order, and follow up the production progress for you by taking pictures, videos or inviting you to the factory for inspection

5. Complete production, 100% QC qualified after shipment

You pay the balance and wait for the delivery

6. After-sales service, if you have any quality problems after receiving the goods, we will provide you with a complete after-sales solution

FAQ

Q1. What if I want to customize a part but I can't draw?

We can also provide design service as long as you tell us all your requirements.

Q2. How do you ship the goods and how long does it take to arrive?

We usually ship by DHL, UPS, FedEx or TNT. It usually takes 3-7 days to arrive. Airline and sea shipping are also optional.

Q3. How to proceed an order?

Let us know your requirements or applications first. Secondly, we quote according to your requirements or our suggestions. Thirdly, the customer confirms the samples and pays a deposit for the formal order. Finally, we arrange production.

Q4. All colors of the product are the same, is the surface treatment the same?

No. With powder coatings, bright colors will stand out over white or gray. Regarding anodizing, color is higher than silver, and black is higher than color.

Q5. Will it be safe after you get our drawings?

Yes, we can sign a non-disclosure agreement before receiving the drawings.

Why choose us?

- We are passionate about providing our customers with the highest level of customer service and satisfaction.

- Our company implements strict quality control system, adheres to the belief that quality is based on the market and wins the market with reputation, which makes us deeply favored by enterprises at home and abroad.

- We offer a range of stamping parts products with exceptional quality and value.

- People are the first factor in productivity, and they are both the main body of the enterprise and the core of enterprise management.

- Our stamping parts products are designed to meet the most demanding industry standards and regulations.

- Our company has strong technical force and strong product R & D ability. We can customize special Stamping Surface Cover according to customer requirements to meet different needs.

- Our stamping parts products are designed to provide optimal performance, maximum efficiency, and long service life.

- We meet your needs with thoughtful service and good reputation to welcome new and old customers to visit us.

- As a manufacturer and supplier, we offer competitive prices on all of our stamping parts products.

- Our company has advanced Stamping Surface Cover processing equipment and development tools. With many years of production experience and strong professional and technical personnel, we constantly update technology and improve management, and now we have developed into a powerful enterprise with modern management concepts and modern production models.

Hot Tags: stamping surface cover, China stamping surface cover manufacturers, suppliers, factory, Stamping Aluminium Cover, Stamped Battery Hardware, Stamping Precision Bending Parts, Stamping Battery Shrapnel, Stamped Shield, Stamped Panel