Introduction:

Stamped motor housing is one of the essential components in the manufacturing of electric machines. It serves as the outer casing of an electric motor that protects the components inside and supports the machine's rotational movement. The motor housing must be made with precision and high-quality materials to ensure its durability and longevity.

As a leading manufacturer located in China, we specialize in producing stamped motor housing for various applications. Our motor housing is lightweight, robust, and made of high-quality materials. It is designed to withstand harsh conditions, resist corrosion, and ensure long-lasting performance.

Features and Benefits:

1. High-Quality Materials:

Our stamped motor housing is crafted from top-notch materials, including aluminum, steel, and brass. These materials are selected based on their strength, durability, and resistance to corrosion. Our high-quality materials also ensure the motor housing's ability to dissipate heat generated during operation, preventing damage to the motor.

2. Customizable Design:

We provide customizable designs to suit specific customer needs. The housing can be made in different shapes, sizes, and colors based on the specifications given by the customer. We have a team of experts who are proficient in developing designs that meet the desired requirements while adhering to industry standards.

3. Precision Engineering:

Our stamped motor housing is manufactured with precision engineering to ensure its structural integrity. The design is optimized for maximum strength and durability, and our manufacturing process employs the latest technologies and state-of-the-art equipment.

4. Cost-Effective:

Our stamped motor housing is cost-effective compared to other options available in the market. We offer competitive pricing without compromising on quality. This makes our product an affordable option for customers seeking a durable and long-lasting motor housing.

5. Corrosion Resistance:

Our stamped motor housing is engineered to be highly resistant to corrosion. It can withstand harsh environments, such as chemicals, moisture, and extreme temperatures, without losing its structural integrity.

6. Lightweight:

Our stamped motor housing is lightweight, making it easier to handle and install. This feature also makes it ideal for applications in the aerospace and automotive industries, where weight is a critical factor.

Conclusion:

Our stamped motor housing is a reliable and durable option for customers seeking high-quality motor housing for their electric machines. We ensure that our product meets the highest standards, from the selection of raw materials to the manufacturing process. Our customizable designs, precision engineering, and cost-effective pricing make us a preferred choice among customers worldwide. For enquiries or orders, please contact us for further information.

Product Specification

Product name | Stamped Motor Housing |

Material | Made to order |

Surface treatment | Anodizing, passivation, electropolishing, baking varnish, powder spraying, electrophoresis, and blackening are all examples of electroplating. |

Production technology | Laser cutting, CNC machining, die-casting, shaping, moulding, tapping, riveting, welding, etc. are a few examples of manufacturing processes. |

OEM/ODM service | Based on client specifications for Stamped Motor Housing |

Color | Special order |

Application | Automobile sheet metal, communication devices, smart terminals, airspace components, medical devices, drone parts, LCD TV backplanes, air conditioners, computers/players, security devices, air purifiers, and appliances for water therapy |

Drawing format | PDF, DXF, DWG, IGS, STP, JPG, BMP, PNG |

To pay | 30% as a down payment, with the rest 70% due before delivery. |

Delivery time | Depending on the quantity, the actual delivery time can range from 3 to 25 days after receiving the deposit. |

Production Benefit

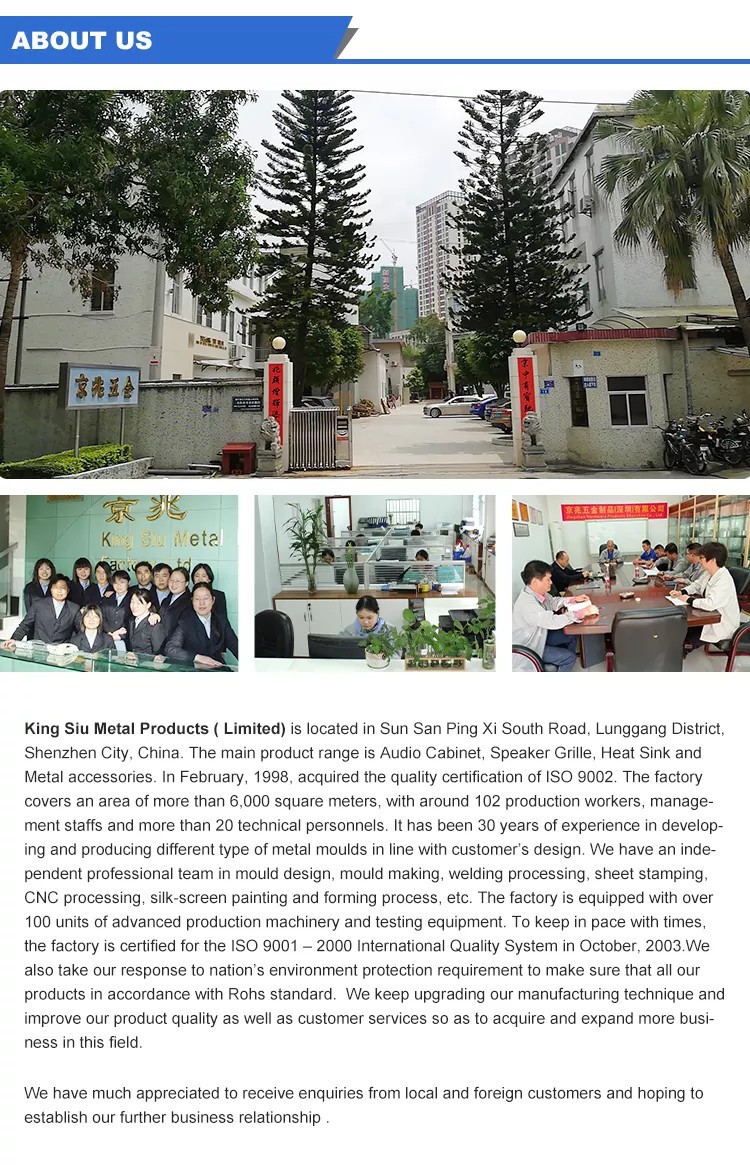

A manufacturer of precision metal stamping with more than 30 years of OEM and ODM one-stop service and ISO9001 certification is King Siu Metal Products (ShenZhen) Ltd. a one-stop shop that can handle everything from mold design to mold creation to manufacturing to welding to surface treatment to assembly to packaging to delivery. Quality Control: We have a qualified team of engineers who supervise the quality. Customer support A dedicated salesman is assigned to each customer to offer prompt technical support and post-purchase assistance.

Product Offering

1. Processing of sheet metal (machine equipment casing, shell, chassis, cabinet, frame, cover, bracket, box, plate, grille, bracket, bracket, sheet metal clip, sheet metal installation, sheet metal, etc... )

2. CNC machining with accuracy (milling, turning, CNC parts)

3. Metal pieces made of aluminum extrusion (aluminum profile, aluminum rapid prototyping, aluminum shell and box)

4. Metal stamped components (laser cutting, bending, welding, riveting, polishing, mirror surface, deep drawing, broaching, passivation, wire drawing, coating, etc....)

Quality Assurance

1) Upon arrival at the factory, raw materials are inspected by incoming quality control (IQC)

2) Thorough examination prior to production line operation

3) Process Quality Control: Complete inspection and inspection during mass manufacturing (IPQC)

4) Conduct a final quality check on the products after they are finished (FQC)

5) Product quality control during shipment inspection (OQC)

FAQ

1. Are you a manufacturing or trading business?

You are welcome to join our factory, which is located at No. 10 Pingxi South Road in the Longgang neighborhood of Shenzhen, China (zip code: 518110).

2. What sort of services do you offer?

Creating molds, metal stamping, CNC machining, assembling, and surface treating.

3. When will my order arrive?

3 to 5 weeks for the mold. Time for mass production: 3 to 4 weeks.

4. How do you rate on quality?

We are certified to ISO 9001.

Once the sample has been approved, we will create the operation instructions.

Before shipping, we will inspect every single item.

Trade assurance from Alibaba can be used for transactions.

5. When can we expect to receive a quote?

Within two days of receiving the complete information (your 2D/3D drawings, samples, and requirements), we will provide you with a quote.

Why choose us?

- Our stamping parts products are ideal for a wide range of applications, including automotive, construction, and aerospace.

- Our company insists on the concept of 'customer is God', and we are eager to meet the needs of customers, to ensure quality and quantity, and to innovate and forge ahead.

- With a wide range of products, we can provide you with all of the stamping parts products you need in one place.

- We have a complete one-stop service of product inspection, packaging, transportation, etc., and have a group of high-quality professional and technical personnel with the ability to continuously develop new products.

- Our stamping parts products are designed to provide maximum efficiency and accuracy in their application.

- Our products have a personalized quality that truly meets the different needs of each customer, and we are constantly optimizing and developing our Stamped Motor Housing.

- Our stamping parts products offer superior quality and performance when compared to other similar products on the market.

- Our company has always implemented the total quality management idea, conducted total quality management training for all the company's personnel, and formulated a detailed quality management system.

- Our stamping parts products are designed to meet the needs of a variety of industries and applications.

- The overall strength of the enterprise continues to grow, the scale advantage grows significantly, the business layout becomes more reasonable, the management level improves significantly, and the cultural connotation continues to accumulate.

Hot Tags: stamped motor housing, China stamped motor housing manufacturers, suppliers, factory, Stamped Back Plate, Stamped Panel, Stamped Motor Housing, Stamped Stainless Steel Bending Parts, Stamping Precision Bending Parts, Stamped Battery Hardware