As a supplier of CNC Steel Parts, ensuring high-quality products is not only a commitment to our customers but also the cornerstone of our long - term business success. In the highly competitive manufacturing industry, quality control of CNC steel parts is a multi - faceted process that involves various key factors. This blog post will delve into these crucial elements that contribute to the overall quality of CNC steel parts.

1. Material Selection

The quality of CNC steel parts starts with the right choice of materials. Different applications require different types of steel, each with its own unique properties such as strength, hardness, corrosion resistance, and machinability. For instance, in aerospace applications, high - strength and lightweight steels are often preferred to meet the strict requirements of flight performance and safety. On the other hand, in the automotive industry, steels with good formability and weldability are commonly used for body parts and engine components.

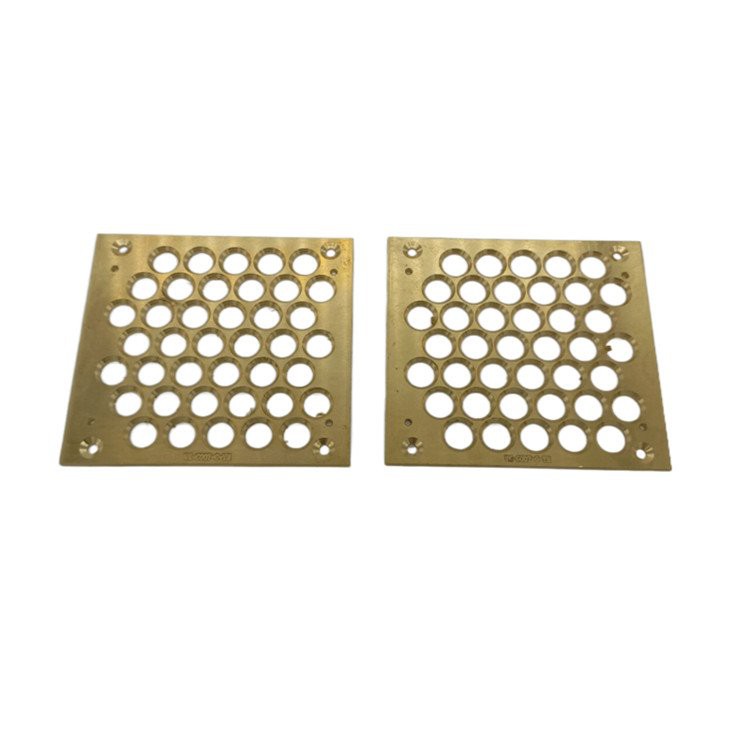

When selecting steel materials, we need to consider factors like chemical composition, mechanical properties, and heat treatment history. A steel with the correct chemical composition ensures that it has the desired strength and corrosion resistance. For example, stainless steel with a sufficient amount of chromium provides excellent corrosion protection. We source our materials from reliable suppliers and conduct thorough inspections upon receipt. This includes material testing using techniques such as spectroscopy to verify the chemical composition and hardness testing to ensure the mechanical properties meet the specifications. CNC Steel Parts

2. Precision Machining Equipment

The quality of CNC steel parts is heavily reliant on the precision of the machining equipment. CNC Milling Machines are at the heart of the manufacturing process. These machines use computer - numerical - control (CNC) technology to precisely control the movement of cutting tools, enabling high - accuracy machining of complex shapes.

Modern CNC milling machines are equipped with advanced features such as high - speed spindles, multi - axis capabilities, and automatic tool changers. High - speed spindles allow for faster cutting speeds, which not only improves productivity but also reduces the cutting forces, resulting in better surface finish and dimensional accuracy. Multi - axis capabilities, such as 5 - axis machining, enable the machining of complex geometries in a single setup, reducing the need for multiple operations and minimizing the potential for errors.

Regular maintenance and calibration of the CNC equipment are essential. We have a strict maintenance schedule in place to ensure that the machines are always in optimal working condition. This includes checking the alignment of the axes, the condition of the cutting tools, and the functionality of the control systems. Any signs of wear or malfunction are immediately addressed to prevent quality issues in the manufactured parts.

3. Skilled Workforce

A skilled workforce is another key factor in the quality control of CNC steel parts. Machinists and operators with extensive experience and training are able to understand the technical requirements of the parts and operate the CNC equipment effectively. They can make real - time adjustments during the machining process to ensure that the parts meet the specified dimensions and surface finish.

Our team of machinists undergoes regular training programs to keep up with the latest advancements in CNC technology and machining techniques. They are also well - versed in reading and interpreting engineering drawings, which is crucial for accurate part production. In addition to technical skills, our workforce is trained in quality control procedures. They are responsible for conducting in - process inspections to detect any potential issues early in the manufacturing process.

For example, during the machining of a complex CNC steel part, an experienced machinist may notice a slight deviation in the cutting path. By making immediate adjustments, they can prevent the production of a defective part, saving time and resources.

4. Quality Control Procedures

Establishing comprehensive quality control procedures is vital for ensuring the quality of CNC steel parts. These procedures cover every stage of the manufacturing process, from raw material inspection to final product testing.

In - process Inspection

In - process inspection is carried out at various stages of machining to monitor the quality of the parts. This includes checking the dimensions of the part using precision measuring tools such as calipers, micrometers, and coordinate measuring machines (CMMs). CMMs are particularly useful for accurately measuring complex geometries and ensuring that the parts meet the design specifications.

Final Inspection

After the machining process is complete, a final inspection is conducted. This involves a more thorough examination of the part, including visual inspection for surface defects, dimensional inspection, and functional testing if applicable. For example, if the CNC steel part is a component of a mechanical system, it may be tested to ensure that it functions properly within the system.

We also maintain detailed records of all inspections and test results. This documentation not only provides traceability but also helps in identifying any recurring quality issues, allowing us to implement corrective actions.

5. Quality Management System

A well - implemented quality management system (QMS) is essential for maintaining consistent quality in the production of CNC steel parts. Our QMS is based on international standards such as ISO 9001, which provides a framework for ensuring that all aspects of the business, from design and development to production and after - sales service, are focused on quality.

The QMS includes procedures for document control, internal audits, management reviews, and corrective and preventive actions. Document control ensures that all relevant information, such as engineering drawings, process instructions, and quality control plans, is up - to - date and accessible to the relevant personnel. Internal audits are conducted regularly to assess the effectiveness of the QMS and identify areas for improvement. Management reviews are held periodically to evaluate the overall performance of the quality management system and make strategic decisions regarding quality improvement.

6. Environmental Factors

Environmental factors can also have an impact on the quality of CNC steel parts. Temperature and humidity can affect the dimensional stability of the parts during machining and storage. For example, in a high - humidity environment, steel parts may be more prone to corrosion.

We maintain a controlled manufacturing environment to minimize the influence of these factors. The temperature and humidity in our production facility are carefully regulated to ensure stable machining conditions. Additionally, proper storage conditions are maintained to prevent damage to the finished parts. The parts are stored in a clean and dry environment, and they are protected from physical damage and corrosion.

7. Supply Chain Management

Effective supply chain management is crucial for ensuring the quality of CNC steel parts. This includes managing relationships with raw material suppliers, tooling suppliers, and other partners in the supply chain.

We work closely with our raw material suppliers to ensure a consistent supply of high - quality materials. We have established long - term partnerships with reliable suppliers and conduct regular supplier evaluations to monitor their performance. This includes assessing their quality control processes, delivery reliability, and pricing.

Tooling suppliers also play an important role. High - quality cutting tools are essential for achieving good surface finish and dimensional accuracy. We select tooling suppliers based on their reputation for providing reliable and high - performance tools. We also work with them to optimize the tooling selection for each specific machining operation.

Conclusion

In conclusion, the quality control of CNC steel parts is a complex process that involves multiple key factors. From material selection and precision machining equipment to a skilled workforce, comprehensive quality control procedures, a well - implemented quality management system, environmental control, and effective supply chain management, every aspect plays a crucial role in ensuring the production of high - quality parts.

As a supplier of CNC Steel Parts, we are committed to maintaining the highest standards of quality in all our products. We understand that the quality of our parts directly impacts the performance and reliability of our customers' products. If you are in the market for high - quality CNC steel parts or CNC Mechanical Parts, we invite you to contact us for a detailed discussion on your specific requirements. We look forward to the opportunity to work with you and provide you with the best - in - class CNC machining solutions.

References

- ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High - Performance Alloys. ASM International.

- ISO 9001:2015 Quality management systems — Requirements. International Organization for Standardization.

- Modern Manufacturing Processes and Materials, by Serope Kalpakjian and Steven R. Schmid. Pearson Education.