What is CNC Milling Machines?

CNC (computer numerical control) milling machines are automated tools that use computer code to cut away material from a block to create precise parts. They are different from manual milling machines because they don't require a human operator.

Why Choose Us

New products

The company independently develops and designs new products with a rich product category.

Professional solution

With rich experience and one-to-one service, we can help you choose products and answer technical questions.

Guarantee quality

Strict production process, to ensure that every product is of high quality.

ODM&OEM

Tailor-made advantages, any product can be customized according to customer needs.

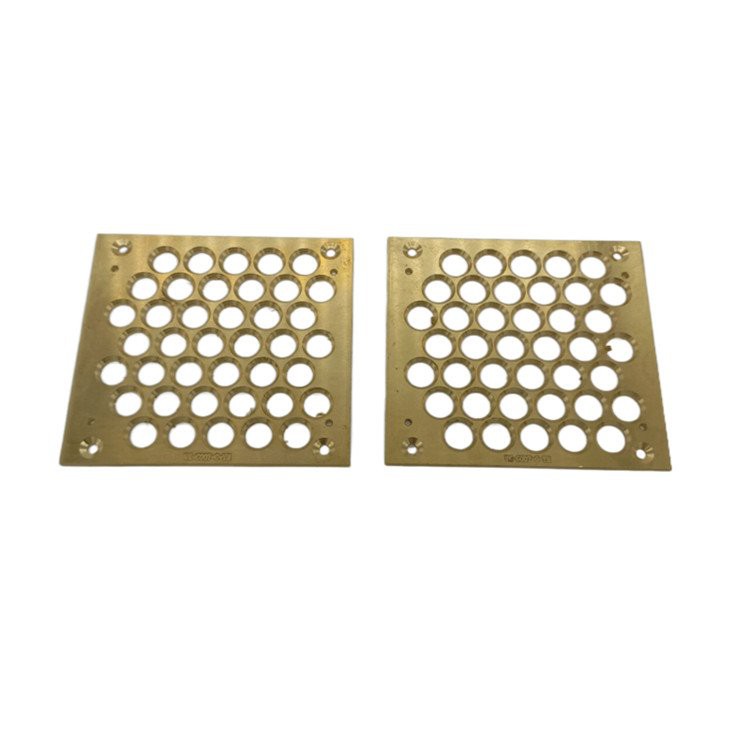

CNC Machined Mechanical Keyboard Shell

Anodized aluminum CNC small CNC milling machine supplier provides CNC machining service for industrial parts.

Small CNC milling machine supplier for anodized aluminum offers CNC machining for industrial products.

Our CNC turning process can produce custom prototypes and end-use production parts in as little as 1 day. We use CNC lathes with power tools so features such as axial and radial holes, flats, grooves and slots can be machined.

The CNC machining process works on a wide variety of materials including metal, plastic, wood, foam and composites and finds applications in a variety of industries including automotive, aerospace, construction and agriculture, enabling the production of a range of product products such as automotive frames, Surgical equipment, aircraft engines, and garden tools, among others.

CNC machining is a subtractive manufacturing process that uses rotating computer-controlled cutting tools, such as drills, end mills, and turning tools, to remove material from solid blocks of material to shape parts. CNC machining eliminates the need to create expensive molds, and manufacturers can start production much faster than with other processes. CNC machining is highly automated and can be produced during and after business hours with minimal human input. What's more, multiple CNC machines can work on the same design and produce the same part at the same time - ultimately shortening production lead times and saving costs.

Utilizing spinning, computer-controlled cutting tools like drills, end mills, and turning tools to remove material from solid blocks of material and shape items, CNC machining is a subtractive manufacturing method. Manufacturing companies may begin production considerably faster with CNC machining than with other methods since it eliminates the need to produce expensive molds. CNC machining may be produced during and after business hours with little to no human involvement because it is highly automated. Additionally, many CNC machines can work simultaneously on the same design to make the same part, which reduces production lead times and costs.

Our modern CNC facilities are capable of producing custom one-off metal and plastic machined parts as well as mass production. Our high speed spindle machines ensure that we achieve excellent surface finishes and reduced cycle times for our customers.

The CNC machining process can be used to produce a wide range of products, including automotive frames, surgical equipment, aircraft engines, and garden tools, among others. It can be applied to a wide range of materials, including metal, plastic, wood, foam, and composites. It also finds applications in a variety of industries, including automotive, aerospace, construction, and agriculture.

Our modern CNC facilities are capable of producing custom one-off metal and plastic machined parts as well as mass production. Our high speed spindle machines ensure that we achieve excellent surface finishes and reduced cycle times for our customers.

Advantages of CNC Milling Machines

Precision

One of the biggest advantages of using CNC milling machines is that they can create parts exactly to specification. Because CNC mills rely on computer instructions to fabricate parts, they eliminate the possibility of human error common in manually operated machines. This means you can accurately create complex parts while achieving tolerances as tight as 0.004mm.

Fast and Efficient

CNC mills feature rotating carousels that can hold up to 30 different tools. These tools are automatically exchanged on the spindle during machining operations, allowing cutting operations to be performed quickly and efficiently. With CNC mills, you can have your parts ready in a matter of hours, whereas conventional methods may take days (or weeks) to complete.

Wide Range of Material Options

CNC mills boast compatibility with a wide range of materials, including plastics, metals, and composites. So long as you've got blocks of the material, CNC mills will have no problem machining it.

Affordability

We can talk about precision, speed, and a ton of other advantages all day, but nothing beats affordability, especially for businesses looking to rely on third-party manufacturers. CNC milling is among the most affordable modern-day manufacturing processes. In fact, a CNC milled component would cost you less than a comparable 3D printed part.

The general principle for a CNC milling machine or CNC machining center is that the part to be machined is clamped on top of the machine table. It could be clamped directly on the table itself, or held in place by a vice or fixture.

The spindle (moving section) including the cutting tool is then either vertically or horizontally positioned. In that configuration, the tool can reach various X-Y-Z positions on the work piece and commence cutting and shaping actions. As it does so, the work piece or part may either be fixed, mounted, or moved/positioned by the table in a linear direction to the spindle with the cutting tool. This allows material to be removed according to the desired shape needed for the machined part. A CNC milling machine may either be horizontal or vertical.

What Are the Different Types of CNC Milling Machines?

Did you know that there are different types of CNC milling machines? So, there could be a type best suited to your needs and requirements. Learn more about the different CNC milling machine types here, and get in touch if you have more questions about which machine may be best suited for your needs.

Vertical CNC Milling Machine

The CNC milling machine's orientation significantly affects the final product. A vertical mill is a very standard type of milling machine, meaning that the spindle axis on the mill is vertically oriented. Vertical CNC milling machines usually have long and thin cutting tools.

Horizontal CNC Milling Machine

The opposite of the vertical CNC milling machine is the horizontal machine which has much shorter and thicker cutting tools. However, Horizontal mills are less versatile and are typically much better suited for long material work, often used to cut gears or for axle machining.

Turret CNC Milling Machine

Turret mills work vertically, and their spindle does not move. At the same time, their table adjusts parallel and perpendicularly to do the cutting job. CNC Turret milling machines are most effective when they remain relatively small. They are best suited to detailed work, such as creating parts for toys and plaques.

CNC Bed Milling Machines

CNC Bed mills are similar to Turret milling machines. Still, the below table only adjusts perpendicularly to perform the cutting, meaning they can be built larger since their frame is more rigid than the Turret. A larger build machine allows for larger jobs, so Bed mills are perfect for milling parts for mid-sized electronics that the Turret mills couldn't handle.

What Are the Main Components of CNC Milling Machine?

Frame

The frame is the main structure that supports the milling machine and helps to give it stability and rigidity. It usually comes with a base and detachable column/s.

An important part of the frame is the machine headstock where the main spindle is mounted on. The headstock, while important, is often overlooked. If the headstock is not rigid and fails to provide stability and support to the spindle, you could get vibrations and chattering during the machining operation. This could result in machining errors and a shorter lifespan to your cutting tool.

Spindle

The spindle can be considered as the "heart" of a CNC milling machine. It normally comprises a rotating assembly, and a tapered section where tool holders may be positioned. The shaft of the spindle is normally where the tool is attached to, usually via a tool holder.

A motor with different levels of transmission is used to rotate the spindle.

To keep your spindle in good condition over the long-term, various forms of lubrication are used. They may include Grease Lubrications (not suitable for long durations of high speed operations), Air-Oil Lubrications (sufficient for longer cycle runs at higher speeds) or the Hwacheon Oil-Jet-Lubrication (ideal for all conditions – even extreme, long and high speed applications).

Depending on the machine type, the spindle can be vertically or horizontally positioned.

Axes

In general, CNC milling machines have X / Y / Z as well as additional rotational axis or C / A or B (subject to configuration). These can be programmed using g-code in the CNC controller.

Column/s

The columns of the CNC machining center can be single (eg travelling column HiRex 4000 or also C-Frame like HiT 400 / 360; VESTA line including "B"; SIRIUS-650 / 850 / 1050) or double (SIRIUS 1250 / 2500 / L1 / L2). This depends on the level of complexity needed in the machining task.

CNC Control Panel

This is the main "nervous system" of the machine tool. It contains the electronics that helps to control the different cutting actions through programming functions. The control panel has a CNC monitor and programming buttons where data and codes can be punched in. It usually also offers a manual function. For ease of machine operation, the control panel should be easily accessible and within easy reach.

Tool / Tool Changers (Automatic Tool Changer Or ATC)

These are either mounted at the column or separately mounted to the machine. The latter is preferred if larger tool changers are needed with 40 up to 300 different tools. Doing so not only helps to save time and effort – it also helps your operators to avoid unnecessary vibrations during operation.

Tool Holders

These come in many different sizes, systems and for various applications. The standard sizes for tool holders are BT 30 to BT 40 and BT 50 (BT refers to the taper angle of the cone on the holder).

Table

The table provides a solid base to clamp the work piece directly on, and can be used to mount fixtures or vice to hold the piece in place. Most of the tables use T-slots for easy clamping of vice, fixture or part.

On Horizontal CNC milling machines, pallets are also available with Tap-holes. These allow greater flexibility in moving different work pieces to be machined. Increasingly, magnets are also being used for easy, fast and secured clamping. These should preferably be built into the machines table to avoid the loss of Z-axis height.

Coolant Tank

Most CNC machining centers have a coolant tank to help supply coolant to the cutting surface or the spindle with tool during machining action. This helps to lengthen the life-span of the machine and its parts. Beyond this, the coolant will also remove heat generated by the machining action, and hence keep temperatures under control.

To hold a sufficient amount of coolant for cutting operations, the rule here is "the more, the better." More coolant helps machine operators to avoid the warming up of coolant.

Industries That Use CNC Milling Machines For Manufacturing Products

Computer numerical controlled (CNC) machining has become a staple in the manufacturing industry. Because of its widespread use, material flexibility, precision, and accuracy, the technology is widely adopted by a number of industries. From automotive to medical and even military, we take a look at some of the industrial applications of CNC milling machines.

Aerospace

The aerospace industry employs CNC milling to produce lightweight, flight-worthy parts of optimal quality. CNC milling techniques deliver exact and accurate parts that serve as prototypes, replacements, transmissions, fuel bodies, manifolds, and even aircraft structures. With the aid of computer numerical software, parts with complex geometries and hollow insides can be built from aluminum and other industrial-grade materials certified for aircraft manufacture.

Automotive

CNC milling has a staple application in the automotive industry, from engine blocks to cylinders, piston rods, and water pumps. CNC milling is the primary technique in the manufacture of OEM parts. The production of lighting parts, such as car headlights and interior lighting, also employs CNC milling technology.

Medical

The medical field widely applies CNC machining to produce sterile and safe equipment. Moreover, equipment like hip stems, biopsy tubes, reamers, bone screws, spacers, inserts, hip cups, and mold cavities are all manufactured utilizing CNC milling. CNC machining plays a significant role in developing prosthetic limbs and appendages, which has greatly enhanced the quality of life for patients.

Energy Sector

In the renewable and non-renewable energy industries, small and large players depend on CNC machines to produce essential components such as valves, turbines, fuel pumps, gears, and gearboxes. CNC provides for the automated manufacturing of high-quality parts that match the demand for precision in the industry.

Military

The production of precision parts for military use also utilizes CNC milling. The applications may range from manufacturing gun components to completing firearm, sidearm, drone, UAVs, and pistol locking.

Consumer electronics

The consumer electronics sector is the most widely dependent industry on CNC machining. The electronic components of Car parts, Televisions, Laptops, Mobile and Smartphones, CPUs, Sound systems, and more are all processed partially or wholly using CNC milling processes.

Agriculture

In producing mechanized agriculture equipment, CNC machines create numerous parts, including gearboxes, transmission housings, incubator components, and other farm equipment. They were all made using CNC milling techniques.

CNC machines are the lifeblood of manufacturing facilities, taking in parts and outputting assemblies ready to be shipped. These machines are used for cutting, drilling, shaping, carving, and other manufacturing tasks. CNC equipment is invaluable in today's assembly line environment due to its high degree of precision that would be impossible or impractical using manual labor.

When CNC machines are down, manufacturing plants can be crippled with thousands of dollars worth of unmet shipments, wasted hours, and lost customers. CNC machine services should include scheduled inspections and preventative measures that can reduce production delays caused by malfunctions. Inspections should include a physical check of the equipment, including the control panel and all parts.

To reap the maximum benefit of CNC machine maintenance, ensure you follow your machine's recommended maintenance guidelines to keep it in tip-top shape. Further, leverage real-time equipment data to enable a usage-based or condition-based maintenance strategy.

Why Do We Need CNC Machine Maintenance?

Without proper CNC machine maintenance, businesses may experience unexpected downtime and production delays. Scheduled inspections and preventive measures are two key ways to ensure these machines stay in good operating condition.

Many users rely on the expertise of maintenance personnel to maintain their machines and avoid any unexpected downtime. According to , 80% of maintenance personnel favor preventive maintenance.

Maintenance Tasks and Procedures for CNC Machine Checks

Since there are various CNC machines, it is important to always adhere to the maintenance guidelines specific to your machine. Other factors, such as the machine's average run time and materials used, can affect how often it needs servicing. In general, CNC machine checks should be done at least once a month. Below, we'll dive into some of the top CNC machine maintenance procedures.

Create a Custom Maintenance Task Schedule

To create a custom maintenance schedule, consider the following tasks:

● Daily Tasks

Inspect all covers, guards, and safety devices

Inspect spindle bearings for oil leakage

Check coolant level and quality; replace coolant as required

● Weekly Tasks

Inspect and adjust machine slideways (if required)

Clean the control cabinet's filter to allow air to pass through for cooling

● Biweekly Tasks

Clean the machine thoroughly with compressed air or a non-flammable solvent such as acetone

● Monthly Tasks

Make any necessary adjustments to limit switches and emergency stops

Inspect the quill area for damage or burrs

Check the condition of all electrical wirings and motor brushes

Our Factory

King Siu Metal Products (Shen Zhen) Limited is located in Sun San Ping Xi South Road, Lunggang District, Shenzhen City, China. The main product range is Audio cabinet, Speaker grille, Heat sink and Metals accessories. In February, 1998, the factory acquired the ISO9002 quality system certification. It covers an area of more than 6,000 square meters, with around 102 employees, management and technical personnel exceed 20 people.

FAQ

Hot Tags: cnc milling machines, China cnc milling machines manufacturers, suppliers, factory, Sheet Metal Back Panel, Sheet Metal Stainless Steel Extrusion, Stamping Bottom Cover, Sheet Metal Press Parts, Sheet Metal L shaped Bending Parts, Sheet Metal Communication Equipment Shell