Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Stamping temperature sensor housing |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

The surface and intrinsic properties of stamping sheets have a great influence on the quality of stamping products. The requirements for stamping materials are:

① Precise and uniform thickness. Stamping molds are precise and have small gaps. Excessive sheet thickness will increase the deformation force, cause material jams, and even swell the die. Too thin sheet material will affect the quality of the finished product, and may even crack during deep drawing.

② Smooth surface, no spots, no scars, no scratches, no surface cracks, etc. All surface defects will remain on the surface of the finished workpiece, and the crack defects may expand in depth and wide during bending, deep drawing, forming and other processes, resulting in waste products.

③ Uniform yield strength, no obvious directionality. Anisotropy (see plastically deformed sheet metal in the stamping process such as deep drawing, flanging, bulging, etc., due to the occurrence of anisotropic yielding successively, the amount of plastic deformation is inconsistent, which will cause uneven deformation and inaccurate forming. defective or waste products.

④ High uniform elongation. In the tensile test, the elongation before the sample begins to appear thin neck is called the uniform elongation. During deep drawing, the deformation of any area of the sheet cannot exceed the uniform extension of the material, otherwise uneven deformation will occur.

⑤ Low yield ratio. The ratio of the yield limit to the strength limit of a material is called the yield ratio. A low yield ratio can not only reduce the deformation resistance, but also reduce the tendency of wrinkling during deep drawing, reduce the amount of springback after bending, and improve the precision of bending parts.

⑥ Low work hardening. The work hardening after cold deformation will increase the deformation resistance of the material and make it difficult to continue deformation, so the plate with low hardening index is generally used. However, materials with a high hardening index have good plastic deformation stability (that is, the plastic deformation is relatively uniform), and localized cracking is not easy to occur.

In actual production, technological tests similar to the stamping process are commonly used, such as deep drawing performance test, bulging performance test, etc. to test the stamping performance of materials to ensure the quality of finished products and a high pass rate.

Company Information

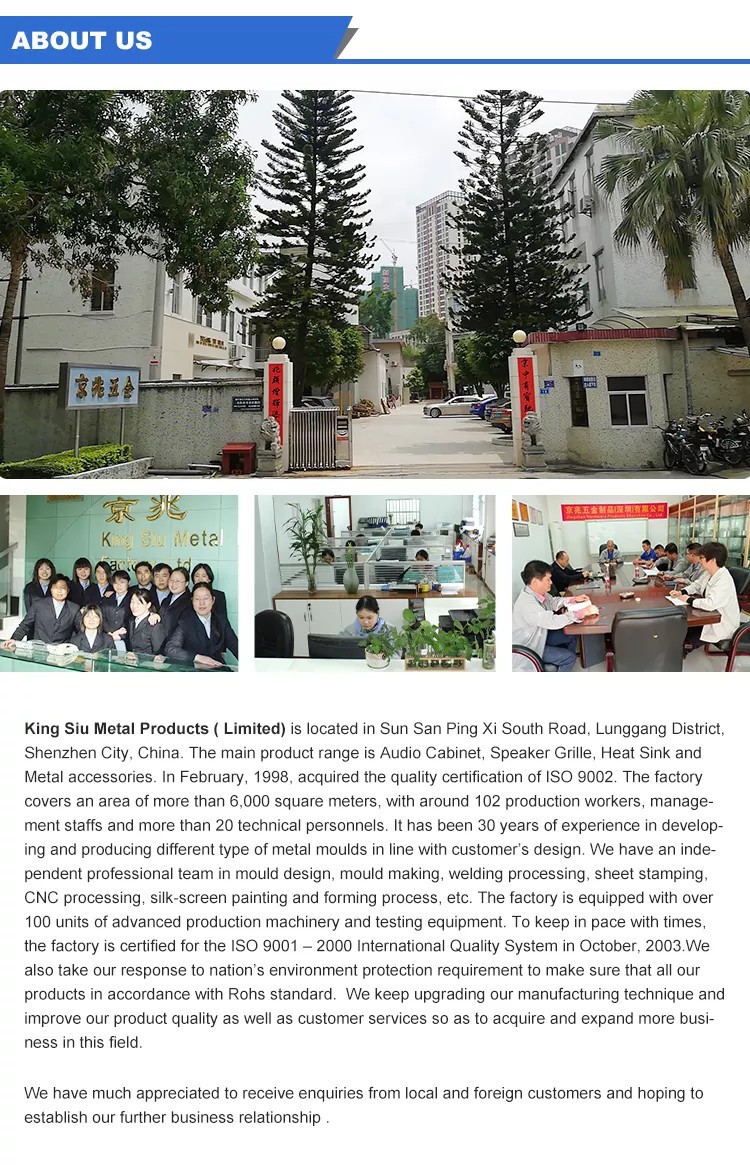

King Siu Metal Products (Shenzhen) Limited was established in 1990, located in Pingsouthwest Road, Xinsheng Community, Longgang District, Shenzhen, China.

The factory covers an area of more than 8,000 square meters, mainly producing hardware accessories such as audio machine shell, horn net and heat sink. Has passed ISO9001 and ISO9002, quality certification system. By professional production personnel to provide production process, including mold design, mold manufacturing, stamping forming, welding, pretreatment, oil spray screen printing, equipped with advanced production equipment!

FAQ

What is your MOQ? Can I mix different styles to a start order?

Please tell us what products you need first. Like compression fittings, the MOQ is 100pcs.But we can provide any stock as samples for you to check the quality first.

Do you offer OEM service and can you produce as our drawings?

Yes. We offer OEM service. We accept custom design and we have a professional design team who can design products based on your requirements. And we can develop new products according to your samples or drawing.

Hot Tags: stamping temperature sensor housing, China stamping temperature sensor housing manufacturers, suppliers, factory, Stamped Camera Housing, Stamped Shield, Stamping Surface Cover, Stamping Battery Shrapnel, Stamped Motor Housing, Stamped Housing Parts