Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Stamped shield |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

◆Stamping processability of Stamped shield stretched parts:

1) Deep drawing concept

A stamping method that uses a die to stamp a flat plate blank into hollow parts with various openings, or to press the finished hollow parts into hollow parts of other shapes and sizes.

◆Classification of drawing process:

1) According to the change of wall thickness:

① General deep drawing (the wall thickness of the workpiece remains unchanged)

② Thinning and deep drawing (the wall thickness of the workpiece becomes thinner)

2) According to the shape of the blank used:

① The first deep drawing (using a flat blank)

② Subsequent deep drawing (with the open hollow part as the blank)

◆Surface treatment of stamping parts:

The surface treatment of stamping products includes electroplating (zinc, cadmium, copper, chromium, tin, nickel, gold, silver, etc.), electrostatic spraying, painting, electrophoresis, screen printing and other treatment methods. Widely used are plastic spraying, spray painting, blackening, electrophoresis, galvanizing, nickel plating, etc.

Company Information

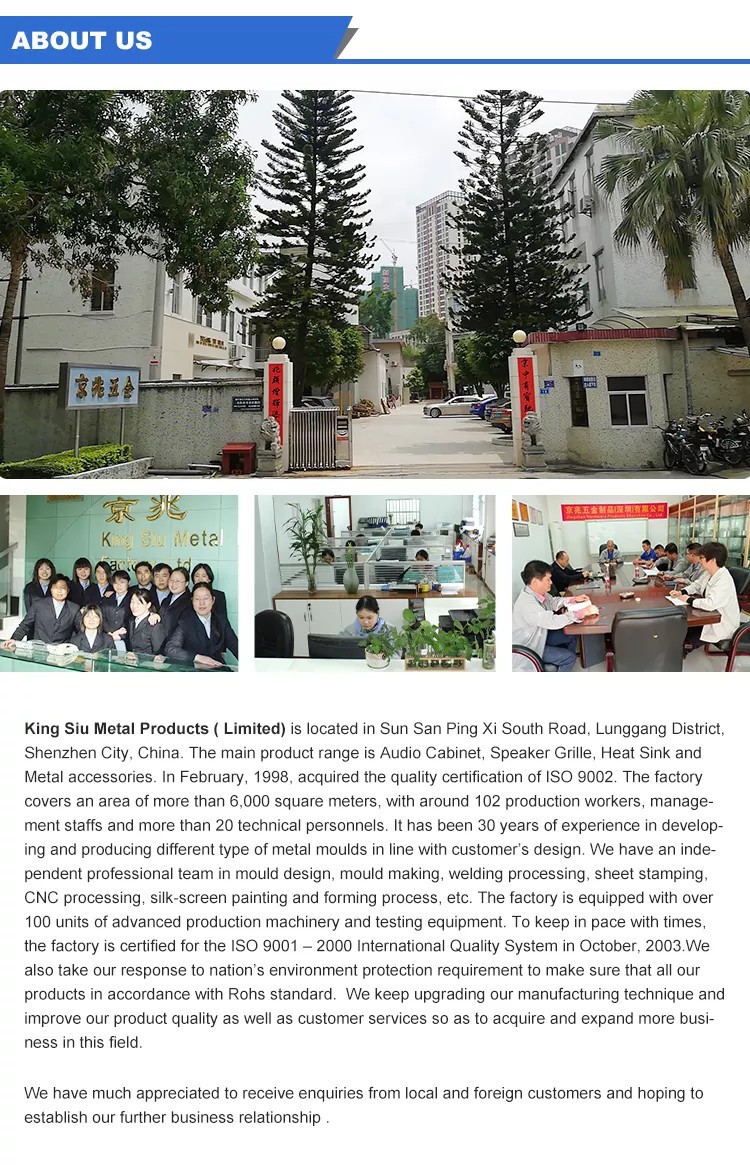

King Siu Metal Products (Shenzhen) Limited's main business scope is manufacturing and processing metal parts, Products are well received by domestic and foreign famous electrical manufacturers such as SONY, PHILIPS, TOSHIBA, THOMSON, SHARP, ALTEC, OLYMPUS, CLARION, EASTECH, JVC, BOSE, HARMAN, CISCO, VTECH, YAMAHA, MARTION AUDIO and other trust.

FAQ

Packaging & Shipping?

Packaging:

1. One piece in one carry bag

2. Suitable quantity to an export carton

3. No other packing accessories in regular

4. Customer required packing is available

Shipping: by air, sea, or express

Sample lead time: 5~7 days

Delivery time: about 25~30 days after order details and production confirmed.

Hot Tags: stamped shield, China stamped shield manufacturers, suppliers, factory, Stamping Bottom Cover, Stamping Temperature Sensor Housing, Stamping And Drawing Parts, Stamping and Bending Parts, Stamped Shield, Stamping Precision Bending Parts