Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for metal welding parts |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Metal welding parts sheet metal material:

1. Electrolytic plate: SECC (N) (fingerprint resistant plate), SECC (P), DX1, DX2, SECD (stretch plate). Material hardness: HRB50°+-5°, tensile plate: HRB32°~37°.

2. Cold-rolled sheet: SPCC, SPCD (stretch sheet), 08F, 20, 25, Q235-A, CRS. Material hardness: HRB50°+-5°, tensile plate: HRB32°~37°.

3. Aluminum plate; AL, AL (1035), AL (6063), AL (5052), etc.

4. Stainless steel plate: SUS, SUS301 (302, 303, 304), 2Cr13, 1Cr18Ni9Ti, etc. 5. Other commonly used materials are: pure copper plate (T1, T2), hot-rolled plate, spring steel plate, galvanized plate, aluminum profile, etc.

Metal welding parts sheet metal processing technology:

Sheet metal processing technology can basically be divided into: scribing, shearing, square folding, rounding (rolling), bending, seaming or welding, flange making and upper flange and other processes. This section mainly introduces the processes of scribing, roll bending, square bending, biting, and pipe bending.

Company Information

King Siu Metal Products (Shenzhen) Limited is a factory specializing in laser cutting, hardware accessories manufacturing, sheet metal processing and other processing services.

The company has always adhered to the customer-centered approach, focusing on quality management from both hardware and software. On the one hand, it has continuously introduced high-level technology and management personnel, and established an effective and reliable technology and quality management system. On the other hand, it has increased technological innovation. and equipment upgrades. The cutting of various metal materials has the characteristics of fast cutting speed, narrow slit, good incision finish, small deformation, small heat-affected zone, and high efficiency. According to the product 1:1CAD electronic file, it can carry out highly difficult and complex shape fully automatic CNC high-precision flexible flower cutting processing, which not only saves molds, but also does not require scribing and rigid fixtures, and does not apply external force to the workpiece. There is no traditional shearing punch, etc. The formed sagging edge has the advantages of fast processing speed, high precision, good repeatability, no need to open molds, and material saving, etc. It is especially suitable for new product development (can greatly shorten the research and development cycle) and the variety and quantity of non-standard spare parts Urgent production needs for large shipments.

FAQ

What is your main market?

Europe, The North America, South America, Australia, The middle east, and etc.

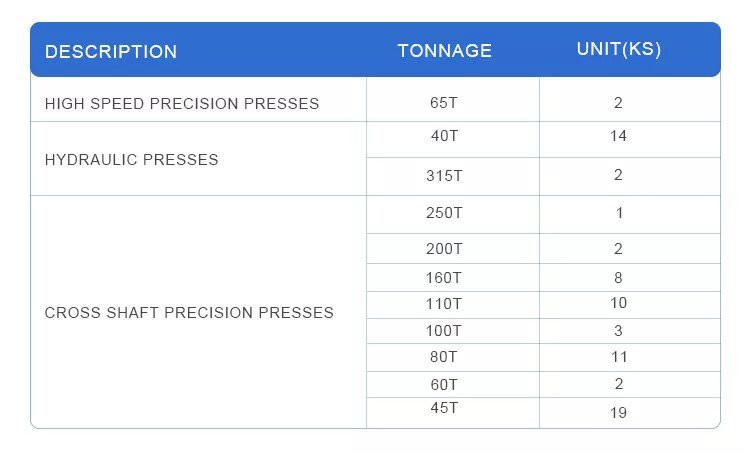

What machines you have in your factory?

Laser cutting machine, high precision cutting machine, robot hand,welding machine, powder coating line, drilling machine, spray paint machine, edge banding machine, and etc.

Can you customize for clients?

Yes, we can customize as your need, we have R&D department, our designers can make design for you and our technicians make prototype.

Do you have a export licence?

Yes.

Hot Tags: metal welding parts, China metal welding parts manufacturers, suppliers, factory, Sheet Metal For Car Welding, Metal Welding Parts