Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for sheet metal for car welding |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Some materials suitable for surface treatment of sheet metal for car welding:

Applicable materials for decorative chrome plating: aluminum alloy-5052, brass-H59, brass-H62, copper-T2, aluminum alloy-1060.

Applicable materials for baking paint: aluminum alloy-5052, stainless steel-304, cold-rolled plate-SPCC, Q235 (A3 steel) 45 steel, aluminum alloy-1060, stainless steel-201.

Applicable materials for plastic spraying: aluminum alloy-5052, stainless steel-304, cold-rolled plate-SPCC, Q235 (A3 steel), 45 steel, aluminum alloy-1060, stainless steel-201.

Applicable materials for spraying Teflon: aluminum alloy-5052, stainless steel-304, aluminum alloy-1060, stainless steel-201.

Sandblasting, silk screen printing, laser marking Applicable materials: aluminum alloy-5052, stainless steel-304, brass-H59.

Brass-H62, copper-T2, cold-rolled sheet-SPCC, galvanized sheet-SGCC, Q235 (A3 steel), 45 steel, aluminum alloy-1060, stainless steel-201, electrolytic sheet-SECC.

Applicable materials for blackening: cold-rolled plate-SPCC, Q235 (A3 steel), 45 steel.

Applicable materials for drawing: aluminum alloy-5052, stainless steel-304, cold-rolled sheet-SPCC, galvanized sheet SGCC, Q235 (A3 steel), 45 steel, aluminum alloy-1060, stainless steel-201, electrolytic plate-SECC.

Applicable materials for electrolytic polishing: stainless steel-304, stainless steel-201.

Passivation applicable materials: stainless steel-304, brass-H59, brass-H62, copper-T2, stainless steel-201.

Company Information

King Siu Metal Products (Shenzhen) Limited was established in 1990, located in Pingsouthwest Road, Xinsheng Community, Longgang District, Shenzhen, China.

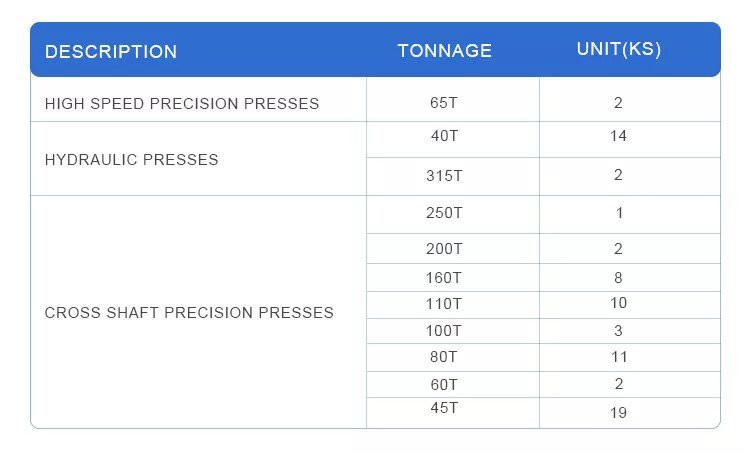

The factory covers an area of more than 8,000 square meters, mainly producing hardware accessories such as audio machine shell, horn net and heat sink, sheet metal for car welding. Has passed ISO9001 and ISO9002, quality certification system. By professional production personnel to provide production process, including mold design, mold manufacturing, stamping forming, welding, pretreatment, oil spray screen printing, equipped with advanced production equipment!

Quality Inspection

After quality inspection before delivery, there are ISO9001, ISO9002 quality certification certificate.

It goes through fall testing, corrosion testing, rust testing, salt spray testing, etc.

Delivery time is generally 10-30 days, the specific time depends on the number of products.

FAQ

Do you have after-sale service?

Yes, Good after-sale service, handling the customer complaint and solve problem for customers.

Can you arrange shipment for customer?

Yes, very good experience in shipping, we work with the most reliable shipping companies in the world, such as OOCL, Mearsk, MSC,and etc.

How can I get more details about conveyor belt?

1. Email: ks009@kingsiu.com; 2. Visit our factory

What is your MOQ? Can I mix different styles to a start order?

Please tell us what products you need first. Like compression fittings, the MOQ is 100pcs.But we can provide any stock as samples for you to check the quality first.

Hot Tags: sheet metal for car welding, China sheet metal for car welding manufacturers, suppliers, factory, Metal Welding Parts, Sheet Metal For Car Welding