Introduction

Sheet metal bending is a fabrication process that involves the manipulation of sheet metal using specialized machines. Bending manipulates the shape and size of sheet metal parts to facilitate their use in a wide range of industrial sectors. At our manufacturing plant in China, we specialize in the production of high-quality sheet metal bending parts that consistently meet the needs of discerning clients.

Our sheet metal bending parts come in various shapes and sizes, and they are made using advanced metalworking techniques to give them the finish, durability, and strength required to withstand the stresses of daily use. We understand the exacting standards of international clients and always work hard to deliver precision products designed to serve you for years to come.

Features and Benefits

Our sheet metal bending parts boast numerous unique features and benefits that set them apart from competing products in the market. These include:

1. High Precision - Our sheet metal bending parts are manufactured using sophisticated machinery that ensures they are of the highest standard and meet stringent industry regulations. We use cutting-edge technology and equipment to produce parts that have tight tolerances and consistent specifications.

2. Superior Finish - Our sheet metal bending parts undergo intensive polishing and deburring processes to ensure smooth edges that prevent injuries and damage to equipment.

3. Durable and Long-Lasting - Our sheet metal bending parts have high tensile strength, ensuring they can withstand external stresses like intense heat, pressure, weather, and chemicals. The materials we use in our manufacturing processes have been tested against various harsh conditions, ensuring their durability and longevity.

4. Versatile and Flexible- Our sheet metal bending parts can be customized and fabricated to meet a wide range of unique client requirements, including size, shape, and material.

5. Cost-Effective - We offer highly competitive pricing on our sheet metal bending parts, while maintaining high standards. This ensures we provide excellent value for money to our clients.

Applications of Sheet Metal Bending Parts

Our sheet metal bending parts can be used for a wide range of applications across different industries, including:

1. Automotive - In the auto industry, sheet metal bending parts are used as components for car bodies, engine systems, and many other parts. Our parts have consistent quality and impressive durability, making them ideal for the harsh conditions of the automotive industry.

2. Aerospace - Sheet metal bending parts are a critical aspect of the aerospace industry. Our parts are lightweight, strong and can withstand the high-altitude conditions of flying.

3. Construction - Sheet metal bending parts are found in various aspects of the construction industry, including doors, windows, roofs, and cladding. Our parts are reliable and can withstand harsh weather conditions and maintain their structural integrity.

4. Medical and Dental - Sheet metal bending parts can be used to manufacture components for medical and dental equipment, including surgical tools, braces, and implants.

Conclusion

In summary, our manufacturing company in China produces high-quality sheet metal bending parts that are highly durable, versatile, and most importantly, cost-effective. Our parts are designed and fabricated to meet the exacting standards of our clients, and we pride ourselves on our attention to detail and high-quality finishing. Our sheet metal bending parts are suitable for use in various industrial sectors, including the automotive, aerospace, construction, and medical industries. As a manufacturer with a reputation for excellence, we guarantee our clients the highest level of satisfaction with all our products. Contact us today to learn more about our products and services!

Product Specification

Material | Aluminum, brass, bronze, copper, hardened metals, precious metals, stainless steel, steel alloys, etc. |

Surface Treatment | According to your request |

Processing | Broaching, drilling, etching, chemical processing, laser processing, milling, rapid prototyping, turning, welding, etc. |

Certificate | ISO 9001, SGS, material certificate |

Drawing Format | CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Color | Customize |

Custom | Customized according to drawings, customized according to samples for sheet metal bending parts |

Use industry | Ship/fastener/industry/outdoor and other industries |

Product Description

An indispensable process in the processing of stainless steel sheet metal parts is bending. The so-called bending is a stamping process that uses pressure to deform the material to form a certain angle and curvature. Commonly used bending includes V-bending, Z-bending and isobaric bending. The most important thing in bending is to pay attention to these points: bending height, bending radius, bending direction, and the bending gap. This page is a bending product customized by customers in the past. Stainless steel bending has certain difficulties. Usually used for bending stainless steel 301 stainless steel and 304 stainless steel.

Due to its good ductility, 301 stainless steel can be better deformed during bending, and 304 stainless steel is the most commonly used stainless steel.

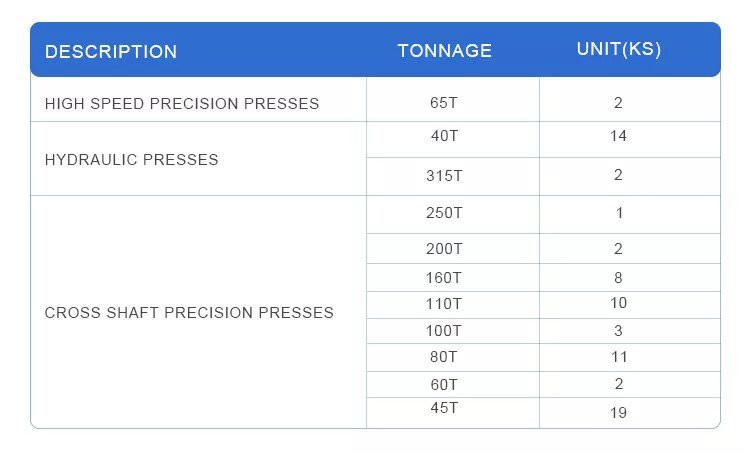

As a manufacturer with rich industry experience, King Siu Metal Product (Shenzhen) Limited has extensive experience in producing various customized products, sheet metal parts and machined parts or 3D printed or plastic parts for customers. We have sufficient The production power, choose the most suitable material and the most suitable process according to the customer's requirements, and the most suitable processing method to produce the highest quality products

Production Advantage

1. Good flexibility

The CNC bending machine has good flexibility after processing, no need for tools and molds, combined with CAD/CAM technology, it can cut plates of any shape and size, especially suitable for cutting multi-variety, small-batch, and complex-shaped parts.

2. High processing efficiency

Bending cutting is non-contact processing, no impact of mechanical blanking, no wear of tools and molds, no mechanical blanking and blanking when overlapping blanking, the workpieces are arranged tightly, which can save 20%-30% of materials, and one-time forming without cutting Subsequent processing.

3. High precision

The curved cutting incision is narrower and smoother, without rounded corners and mechanical cutting. The heat-affected zone, thermal stress and thermal deformation are small.

FAQ

1. How soon can I get samples?

Depending on your specific project, it usually takes 10 to 20 days.

2. What if I am not completely satisfied with the parts I receive?

We guarantee that we will comply with your requirements, including surface treatment, Material, workmanship, allowable tolerances, etc. Any changes that can not be made or are desired will be communicated to you in advance. If you have high requirements or are still not at ease, we will timely send samples to you before shipment to ensure that it really meets your requirements before shipment.

3. Will my drawing be divulged if you benefit?

No, we pay much attention to protect our customer’s privacy of drawings, signing NDA is also accepted if need.

Why choose us?

- Our company is a reliable and trustworthy source for Metal Sheet Parts.

- Our employees use their knowledge persistently to create new Sheet Metal Bending Parts.

- We are a Chinese factory specializing in high-quality metal sheet parts and professional services.

- We monitor service quality in three dimensions, and we uphold the service concept of "professional, fast, convenient and caring".

- We offer custom Metal Sheet Parts manufacturing services to meet our customers' unique needs.

- We will provide high-quality, cost-effective products to customers around the world with the spirit of harmony, rigor, innovation and efficiency.

- We are committed to delivering Metal Sheet Parts that are both functional and aesthetically pleasing.

- The perfect enterprise mechanism and management system enable our company to maintain its youth and vitality in the fierce market competition.

- Our Metal Sheet Parts are available in various shapes, sizes, and materials for customization.

- Our team adheres to the principles of truthfulness, gratitude and happiness, and practices the values of honesty, dedication and innovation.

Hot Tags: sheet metal bending parts, China sheet metal bending parts manufacturers, suppliers, factory, Sheet Metal L shaped Bending Parts, Sheet Metal Medical Equipment Housing, Sheet Metal Housing Parts, Sheet Metal Bracket, Sheet Metal Stainless Steel Bending Parts, Sheet Metal Extrusions