CNC (Computer Numerical Control) milling machines have revolutionized the mold - making industry with their precision, efficiency, and versatility. As a leading supplier of CNC milling machines, I've witnessed firsthand how these advanced tools are reshaping the way molds are designed and manufactured. In this blog, I'll explore the various applications of CNC milling machines in the mold - making industry.

Precision Molding and High - Quality Surface Finish

One of the primary applications of CNC milling machines in mold - making is the production of molds with high precision and excellent surface finishes. In industries such as automotive, aerospace, and consumer electronics, molds need to be extremely accurate to ensure the quality of the final products. CNC milling machines use computer - controlled movements to cut and shape materials with micron - level precision.

For example, when manufacturing injection molds for plastic parts, the mold cavity must be machined to exact specifications. Any deviation in the dimensions can lead to defective parts. CNC milling machines can achieve tight tolerances, ensuring that the molds produce parts that meet the strictest quality standards. Moreover, these machines can create smooth surface finishes on the mold, which is crucial for the appearance and functionality of the molded parts. A smooth mold surface reduces friction during the molding process, making it easier to eject the parts and also gives the parts a better aesthetic appeal.

Complex Geometries and Intricate Designs

Molds often require complex geometries and intricate designs to produce parts with unique shapes and features. CNC milling machines are well - suited for this task. They can execute multi - axis machining operations, allowing for the creation of three - dimensional shapes that would be difficult or impossible to achieve with traditional machining methods.

In the jewelry and watch - making industries, molds for delicate and detailed components are frequently needed. CNC milling machines can carve out intricate patterns, curves, and undercuts on the mold surfaces. This ability to machine complex geometries also extends to the production of molds for medical devices. For instance, molds for surgical instruments may require complex internal channels and precise contours, which can be accurately machined using CNC milling technology. The flexibility of CNC milling machines enables mold makers to bring their creative and functional designs to life.

Prototyping and Rapid Tooling

CNC milling machines play a vital role in the prototyping and rapid tooling processes within the mold - making industry. Before mass - producing a mold, it's essential to create a prototype to test the design and functionality. CNC milling machines can quickly produce prototype molds from a variety of materials, including aluminum, steel, and plastics.

This rapid prototyping capability allows mold designers to make adjustments and improvements to the design based on the test results. It significantly reduces the time and cost associated with traditional prototyping methods. Once the prototype is approved, the same CNC milling machine can be used to produce the final production mold. This seamless transition from prototyping to production is a major advantage of using CNC milling machines in the mold - making process.

Material Versatility

Another significant application of CNC milling machines in mold - making is their ability to work with a wide range of materials. Different molds require different materials depending on the application and the properties of the parts to be molded. CNC milling machines can handle materials such as steel, aluminum, brass, and even exotic alloys.

For example, steel molds are commonly used for high - volume production due to their durability and strength. Aluminum molds, on the other hand, are lighter and more cost - effective for low - volume production or prototyping. CNC milling machines can efficiently machine these different materials, adjusting the cutting parameters according to the material's hardness, density, and other properties. This material versatility gives mold makers the flexibility to choose the most suitable material for each specific project.

Automation and Productivity

In today's competitive manufacturing environment, productivity is key. CNC milling machines offer a high degree of automation, which increases efficiency and reduces labor costs in the mold - making industry. Once the machining program is set up, the CNC milling machine can operate continuously with minimal human intervention.

Automated tool changers allow the machine to switch between different cutting tools during the machining process, enabling the completion of multiple operations in a single setup. This reduces the time spent on manual tool changes and setup adjustments. Additionally, CNC milling machines can be integrated into a manufacturing cell or a production line, further streamlining the mold - making process. The high - speed machining capabilities of modern CNC milling machines also contribute to increased productivity, allowing for faster material removal rates and shorter machining times.

Applications in Specific Mold - Making Processes

Injection Molding

Injection molding is one of the most common molding processes, used to produce a wide range of plastic parts. CNC milling machines are used to create the injection molds, which consist of two main parts: the cavity and the core. The cavity is where the plastic material is injected, and the core forms the internal shape of the part.

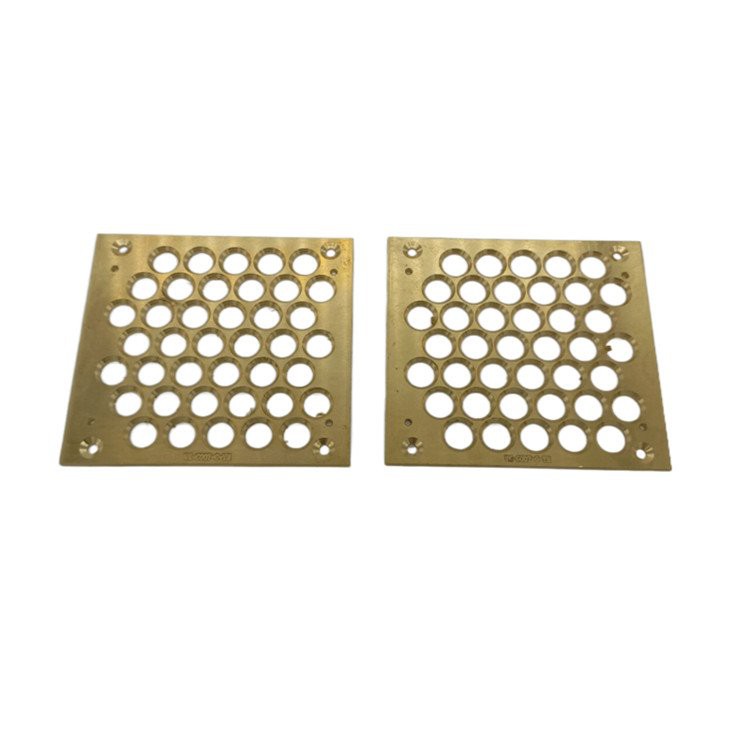

CNC milling machines can precisely machine the cavity and core, ensuring proper alignment and fit. They can also create cooling channels within the mold to control the temperature during the injection process. These cooling channels are critical for reducing the cycle time and improving the quality of the molded parts. Brass CNC Turned Parts can be used as inserts or other components in injection molds, and the precision machining capabilities of CNC milling machines are essential for their production.

Die - Casting Molds

Die - casting is a process used to produce metal parts by injecting molten metal into a mold cavity. CNC milling machines are used to manufacture die - casting molds, which need to withstand high temperatures and pressures. The molds must be machined with high precision to ensure the quality of the die - cast parts.

CNC milling machines can create the complex shapes and details required for die - casting molds, such as the gating system and the ejector pin holes. They can also machine the mold surfaces to a high degree of smoothness to prevent the metal from sticking during the casting process. CNC Mechanical Parts are often used in the construction of die - casting molds, and the accurate machining of these parts is crucial for the proper functioning of the molds.

Compression Molding

Compression molding is used to produce parts from thermosetting plastics and rubber. CNC milling machines are used to create the compression molds, which are typically made of steel. The molds need to have a precise shape and surface finish to ensure uniform compression of the material.

CNC milling machines can machine the mold cavities and cores to the required dimensions, as well as create any necessary vents and flash grooves. The ability to machine complex geometries allows for the production of compression molds for parts with unique shapes and features. CNC Machined Metal Components can be incorporated into compression molds to enhance their performance and durability.

Conclusion

CNC milling machines have become an indispensable tool in the mold - making industry. Their precision, ability to handle complex geometries, material versatility, and automation capabilities make them ideal for a wide range of mold - making applications. Whether it's for injection molding, die - casting, or compression molding, CNC milling machines can help mold makers produce high - quality molds efficiently and cost - effectively.

If you're in the mold - making industry and looking for a reliable CNC milling machine supplier, we're here to assist you. Our company offers a wide range of CNC milling machines with advanced features and technologies to meet your specific requirements. Contact us today to discuss your project and explore how our CNC milling machines can enhance your mold - making processes.

References

- Groover, M. P. (2010). Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. Wiley.

- Kalpakjian, S., & Schmid, S. R. (2009). Manufacturing Engineering and Technology. Pearson Prentice Hall.

- Stephenson, D. A., & Agapiou, J. S. (2006). Metal Cutting Theory and Practice. CRC Press.