As a seasoned supplier of CNC Mechanical Parts, I've witnessed firsthand the pivotal role these components play in various industries. From aerospace to automotive, the durability of CNC mechanical parts is not just a preference but a necessity. In this blog, I'll share insights on how to ensure the longevity of these essential parts, drawing from my years of experience in the field.

Material Selection: The Foundation of Durability

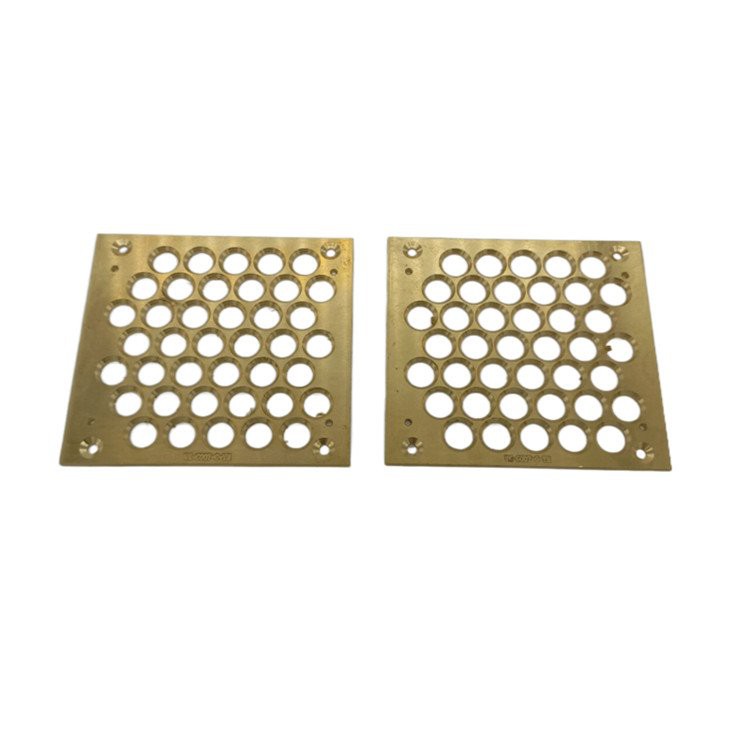

The journey to durable CNC mechanical parts begins with the right material selection. Different applications demand different material properties, and choosing the wrong material can lead to premature failure. For instance, Brass CNC Turned Parts are known for their excellent corrosion resistance and machinability, making them ideal for applications in plumbing and electrical systems. On the other hand, CNC Machining Aluminum Part offer a high strength-to-weight ratio, making them suitable for aerospace and automotive applications where weight reduction is crucial.

When selecting a material, consider factors such as strength, hardness, corrosion resistance, and thermal conductivity. It's also important to ensure that the material is compatible with the manufacturing process and the intended application. For example, if the part will be exposed to high temperatures, a material with good thermal stability should be chosen.

Precision Machining: Ensuring Quality and Consistency

Once the material is selected, the next step is precision machining. CNC machining is a highly accurate and repeatable process that allows for the production of complex parts with tight tolerances. However, to ensure the durability of the parts, it's essential to use the right machining techniques and equipment.

One of the key factors in precision machining is the choice of cutting tools. High-quality cutting tools can significantly improve the surface finish and dimensional accuracy of the parts, reducing the risk of stress concentrations and premature failure. It's also important to use the correct cutting parameters, such as speed, feed, and depth of cut, to ensure that the material is machined efficiently and effectively.

In addition to using the right cutting tools and parameters, it's also important to have a well-maintained machining environment. This includes keeping the machines clean, lubricated, and calibrated, as well as ensuring that the workpieces are properly fixtured and supported. By maintaining a high level of precision and consistency in the machining process, the durability of the parts can be significantly improved.

Surface Treatment: Enhancing Performance and Protection

Surface treatment is another important aspect of ensuring the durability of CNC mechanical parts. Surface treatments can improve the hardness, corrosion resistance, and wear resistance of the parts, as well as enhance their aesthetic appearance. There are several types of surface treatments available, including plating, coating, and heat treatment.

Plating is a process in which a thin layer of metal is deposited onto the surface of the part to improve its corrosion resistance and appearance. Common plating materials include chrome, nickel, and zinc. Coating is a similar process, but it involves the application of a thin layer of a non-metallic material, such as paint or powder coating, to the surface of the part. Coating can provide additional protection against corrosion, wear, and UV radiation.

Heat treatment is a process in which the part is heated to a specific temperature and then cooled at a controlled rate to change its physical and mechanical properties. Heat treatment can improve the hardness, strength, and toughness of the part, as well as reduce its internal stresses. Common heat treatment processes include annealing, quenching, and tempering.

By choosing the right surface treatment for the part, its performance and protection can be significantly enhanced, leading to improved durability and longer service life.

Quality Control: Ensuring Compliance and Reliability

Quality control is an essential part of the manufacturing process, especially when it comes to ensuring the durability of CNC mechanical parts. Quality control involves the inspection and testing of the parts at various stages of the manufacturing process to ensure that they meet the required specifications and standards.

One of the key aspects of quality control is dimensional inspection. This involves measuring the dimensions of the parts using precision measuring tools, such as calipers, micrometers, and coordinate measuring machines (CMMs). Dimensional inspection ensures that the parts are within the specified tolerances and that they will fit and function properly in the intended application.

In addition to dimensional inspection, it's also important to perform other types of tests, such as hardness testing, material analysis, and non-destructive testing (NDT). Hardness testing measures the hardness of the part, which can affect its wear resistance and strength. Material analysis is used to determine the chemical composition of the part, ensuring that it meets the required specifications. NDT is a non-invasive testing method that can detect internal defects, such as cracks and voids, in the part.

By implementing a comprehensive quality control program, the durability of the parts can be ensured, and the risk of premature failure can be minimized.

Proper Handling and Maintenance: Extending the Service Life

Finally, proper handling and maintenance are essential for extending the service life of CNC mechanical parts. When handling the parts, it's important to use the right tools and techniques to avoid damaging them. This includes using protective gloves, handling the parts gently, and avoiding dropping or banging them.

Once the parts are installed, it's important to follow the manufacturer's recommendations for maintenance and lubrication. This includes regularly cleaning the parts, checking for signs of wear and damage, and replacing any worn or damaged components. By properly maintaining the parts, their performance and durability can be extended, reducing the need for costly repairs and replacements.

Conclusion

Ensuring the durability of CNC mechanical parts is a complex process that involves several factors, including material selection, precision machining, surface treatment, quality control, and proper handling and maintenance. By paying attention to these factors and implementing best practices in the manufacturing process, the durability of the parts can be significantly improved, leading to longer service life and reduced downtime.

If you're in the market for high-quality CNC mechanical parts, I encourage you to contact me to discuss your specific requirements. As a trusted supplier with years of experience in the industry, I can provide you with the expertise and support you need to ensure that you get the best possible parts for your application. Let's work together to achieve your goals and ensure the success of your projects.

References

- "CNC Machining Handbook" by John Doe

- "Materials Science and Engineering: An Introduction" by William D. Callister Jr.

- "Surface Engineering for Corrosion and Wear Resistance" by David S. Rickerby and A. Matthews