Sheet metal extrusion is a manufacturing process in which a sheet of metal is forced through a die to create a desired cross-sectional shape. This process can be used with a variety of metals including aluminum, steel, copper, and more. Sheet metal extrusions are utilized in a wide range of applications, including the construction industry, automotive industry, and more. As a manufacturer in China, we offer high-quality sheet metal extrusions that can be customized to meet your specific needs.

Our sheet metal extrusions are made using the latest manufacturing technologies and techniques. Our team of skilled technicians and engineers work tirelessly to ensure that each extrusion we produce meets the highest standards of quality and reliability. We use only the best materials in the manufacturing process, ensuring that our sheet metal extrusions are strong, durable, and long-lasting.

One of the key advantages of our sheet metal extrusions is their versatility. We can create extrusions in a variety of shapes and sizes, allowing us to meet the specific requirements of your project. Whether you need a simple extrusion or a more complex shape, we can help you create a product that meets your exact specifications.

In addition to their versatility, our sheet metal extrusions are also lightweight and easy to transport. This makes them ideal for use in a wide range of applications where weight and ease of transportation are critical factors. Our extrusions are also easy to install, resulting in significant cost savings and reduced installation time.

Our sheet metal extrusions are also highly customizable. We can work with you to create an extrusion that meets your exact needs, whether you need a specific shape or require a particular finish. We can also provide custom packaging and labeling, ensuring that your extrusions arrive safely and are clearly identified.

Another advantage of our sheet metal extrusions is their durability. Our extrusions are made from high-quality materials that are designed to withstand even the harshest environments. Whether you need an extrusion for a construction project or for use in an automotive application, our products are built to last.

At our manufacturing facility in China, we prioritize quality and reliability above all else. We follow strict quality control processes to ensure that every extrusion we produce meets the highest standards of quality. Our commitment to quality has earned us a reputation as a leading manufacturer of sheet metal extrusions in the industry.

In summary, our sheet metal extrusions offer a wide range of benefits that make them an ideal choice for a variety of applications. From their versatility and customization options to their durability and reliability, our extrusions are sure to meet your specific needs. If you are looking for high-quality sheet metal extrusions, look no further than our team in China. Contact us today to learn more about our products and to discuss your specific needs with one of our experts.

Product Specifications

|

Material |

Carbon steel, stainless steel, galvanized steel, aluminum, copper, brass and other nonferrous alloy materials etc |

|

Surface treatment |

Chrome plating, zinc plating, nickel plating, powder spraying, electrophoresis, dip coating Mirror polishing, etc |

|

Certificate |

ISO 9001, SGS, material certificate.etc |

|

Custom |

Customized according to drawings, customized according to samples for Sheet metal extrusions |

|

Drawing Format |

CAD, DWG, SLDDRW, IGS, STP, SLDPRT, PDF |

Product Information

Main material: 201, 304, 316, 430...

Thickness: 0.3-3.0MM

Surface treatment: 8K, matte, snowflake sand, brushed, no fingerprints, sandblasting, and pattern.

Pplating: Rose gold, champagne gold, French gold, Japanese gold, black rose, red bronze, wine red, coffee, bronze, tea, purple, pink sapphire blue, grass green and other colors.

Water plating process: Black titanium, red bronze, yellow bronze, green bronze.

Etching process: Various patterns such as etched pattern plate.

Embossing process: Embossed sheet roll (pearl, rhombus, free pattern, ice bamboo pattern, stone pattern, antique checkered pattern, etc.)

Company Information

King Siu Metal Products (Shenzhen) Limited's main business scope is manufacturing and processing metal parts, Products are well received by domestic and foreign famous electrical manufacturers such as SONY, PHILIPS, TOSHIBA, THOMSON, SHARP, ALTEC, OLYMPUS, CLARION, EASTECH, JVC, BOSE, HARMAN, CISCO, VTECH, YAMAHA, MARTION AUDIO and other trust.

30 years of cold stamping hardware mold design and production experience.

FAQ

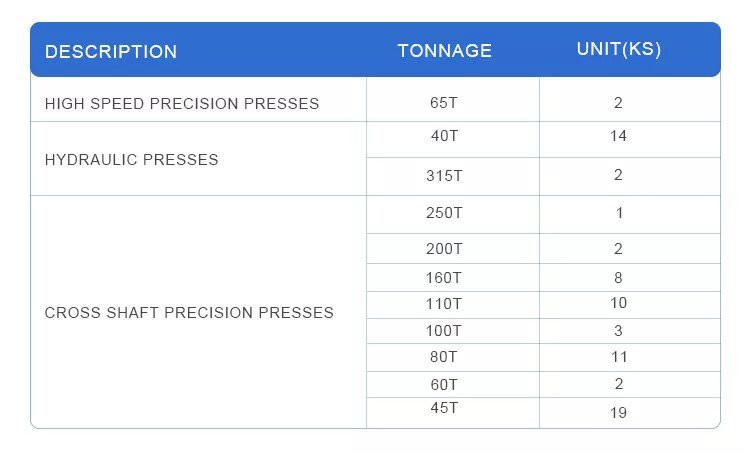

What machines you have in your factory?

Laser cutting machine, high precision cutting machine, robot hand,welding machine, powder coating line, drilling machine, spray paint machine, edge banding machine, and etc.

Do you have QC department?

Yes, we have 12 QC persons.

What is the customer you work with?

We work with famous brands such as: SONY, PHILIPS, TOSHIBA, THOMSON, SHARP, etc.

Why choose us?

- Our Metal Sheet Parts are rigorously tested to guarantee their performance under demanding conditions.

- Only with a good internal environment and corporate ecology can the staff and the company be successful.

- Our team is dedicated to ensuring that the Metal Sheet Parts we produce meet the highest quality standards.

- Our company is a young and innovative enterprise, focusing on the development and production of advanced Sheet Metal Extrusions, and strives to provide solutions for customers at home and abroad. We provide advanced assembly and inspection technologies to improve processes, increase the degree of industrial automation, and enhance the competitive advantage of customers.

- Our Metal Sheet Parts are made with high-quality materials that are resistant to wear and tear.

- Talent is the power source and relying force to promote the scientific development of the company, and is also the starting point and anchor point to realize the leapfrog development of the enterprise.

- We take pride in the quality of the Metal Sheet Parts we produce and stand by our products.

- We are an enterprise full of vitality and vigorous development. We operate with integrity, adhere to the principle of customer first, advocate the entrepreneurial spirit of self-improvement, and follow the quality policy of excellence. Over the years, we have focused on product quality, continuously improved supply efficiency, and established a good reputation among customers.

- Our Metal Sheet Parts are suitable for a wide range of applications.

- We vigorously carry out corporate internal management and corporate culture construction, develop high-quality and low-cost products, and strive to provide customers with satisfactory services and create more wealth for the society.

Hot Tags: sheet metal extrusions, China sheet metal extrusions manufacturers, suppliers, factory, Sheet Metal Battery Shrapnel, Stamping Sheet Metal Parts, Sheet Metal Stainless Steel Shield, Sheet Metal Press Parts, Sheet Metal C shaped Bending Parts, Sheet Metal Shield Shell