As a supplier of CNC steel parts, I've seen firsthand how crucial accuracy is in the manufacturing process. Whether it's for CNC Mechanical Parts, automotive components, or aerospace applications, precision can make or break a project. In this blog, I'll share some of the key factors that can affect the accuracy of CNC steel parts.

Machine Tool Quality

The quality of the CNC machine tool is fundamental. High - end CNC Milling Machines are built with better precision components, such as high - grade ball screws and linear guides. These parts are designed to minimize backlash and provide smooth, accurate motion. Cheaper machines may have looser tolerances, which can lead to inaccuracies in the final parts.

For example, a well - maintained and high - quality machine will have a more stable spindle. A stable spindle ensures that the cutting tool rotates precisely, reducing the chances of vibration and deviation during the machining process. On the other hand, a low - quality spindle might wobble, causing uneven cuts and dimensional errors in the steel parts.

Cutting Tools

The choice of cutting tools is another significant factor. Different cutting tools are designed for specific materials and machining operations. When it comes to steel, carbide cutting tools are often preferred due to their hardness and wear resistance.

Dull cutting tools can be a nightmare. As a tool wears down, it becomes less efficient at removing material. This can result in increased cutting forces, which may cause the workpiece to deform or the tool to deflect. For instance, if a drill bit is dull, it may not drill a hole to the correct diameter, or the hole may have a rough surface finish. Regularly inspecting and replacing cutting tools is essential for maintaining accuracy.

Workpiece Material

The properties of the steel workpiece itself can affect accuracy. Steel comes in various grades, each with different hardness, ductility, and thermal conductivity. Harder steels can be more challenging to machine, as they require higher cutting forces. This can lead to increased tool wear and potential deformation of the workpiece.

Thermal conductivity also plays a role. When machining steel, heat is generated at the cutting interface. If the steel has poor thermal conductivity, the heat can build up, causing the workpiece to expand. Once the part cools down, it may shrink back to a size different from the intended dimensions.

Programming and Setup

Accurate programming is vital. The CNC program controls the movement of the machine and the cutting operations. A small error in the program can lead to significant inaccuracies in the final part. For example, incorrect tool paths or wrong feed and speed settings can result in over - cutting or under - cutting.

Proper setup of the workpiece on the machine is also crucial. If the workpiece is not clamped securely, it can move during machining, leading to dimensional errors. Additionally, incorrect alignment of the workpiece can cause asymmetries in the part.

Operator Skill

The skill of the CNC machine operator cannot be underestimated. An experienced operator can detect and correct potential issues during the machining process. They know how to adjust the machine settings based on the behavior of the cutting tool and the workpiece.

For example, an operator might notice that the machine is making an unusual noise, which could indicate a problem with the cutting tool or the machine itself. A skilled operator will stop the machine, investigate the issue, and take appropriate action to prevent further inaccuracies in the parts.

Environmental Factors

The environment in which the CNC machining takes place can have an impact on accuracy. Temperature and humidity fluctuations can cause the machine and the workpiece to expand or contract. Most high - precision machining facilities try to maintain a stable environment to minimize these effects.

For example, in a hot and humid environment, the steel workpiece may absorb moisture, which can affect its dimensions. Also, the machine components may expand, leading to changes in the machine's accuracy.

Coolant and Lubrication

Using the right coolant and lubrication is important. Coolants help to reduce the heat generated during machining, which can prevent thermal expansion of the workpiece and tool wear. Lubricants, on the other hand, reduce friction between the cutting tool and the workpiece, improving the surface finish and accuracy.

If the coolant is not used correctly or is of poor quality, it may not be effective in cooling the cutting area. This can lead to overheating, which as mentioned earlier, can cause dimensional changes in the part.

Fixturing

Fixturing refers to the devices used to hold the workpiece in place during machining. A well - designed fixture ensures that the workpiece is held securely and accurately. Poor fixturing can lead to movement or vibration of the workpiece, resulting in inaccurate parts.

For example, if a fixture is not rigid enough, it may flex under the cutting forces, causing the workpiece to shift. This can lead to holes being drilled in the wrong location or surfaces being machined at the wrong angles.

Maintenance and Calibration

Regular maintenance and calibration of the CNC machine are essential for maintaining accuracy. Over time, the machine's components can wear out, and its accuracy can degrade. By performing routine maintenance tasks such as lubricating moving parts, checking for loose bolts, and cleaning the machine, we can ensure that it operates at its best.

Calibration is also crucial. A calibrated machine will move to the correct positions and perform cutting operations with the intended accuracy. Without proper calibration, the machine may not follow the programmed tool paths precisely, leading to inaccurate parts.

Conclusion

As a supplier of CNC steel parts, I understand that ensuring accuracy is a multi - faceted challenge. It involves a combination of high - quality equipment, the right cutting tools, skilled operators, and a controlled environment. By paying attention to all these factors, we can produce CNC steel parts that meet the strictest quality standards.

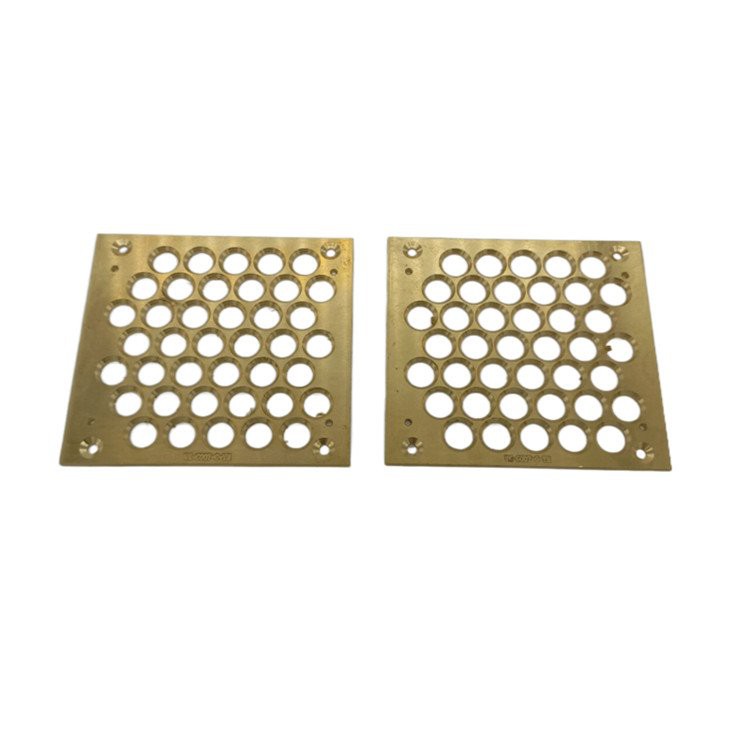

If you're in the market for high - precision CNC Mechanical Parts or Brass CNC Turned Parts, don't hesitate to reach out. We're here to discuss your specific requirements and provide you with top - notch CNC steel parts.

References

- "CNC Machining Handbook"

- "Manufacturing Engineering and Technology" by Serope Kalpakjian and Steven Schmid