Selecting the appropriate spindle speed for CNC mechanical parts machining is a critical decision that can significantly impact the quality, efficiency, and cost of production. As a supplier of CNC Mechanical Parts, I have witnessed firsthand the importance of this parameter in achieving optimal machining results. In this blog post, I will share some insights and guidelines on how to choose the right spindle speed for your CNC machining operations.

Understanding the Basics of Spindle Speed

Spindle speed refers to the rotational speed of the cutting tool in a CNC machine, typically measured in revolutions per minute (RPM). It plays a crucial role in determining the cutting speed, which is the speed at which the cutting edge of the tool moves relative to the workpiece. The cutting speed is a key factor in influencing the material removal rate, surface finish, tool life, and overall machining performance.

Factors Affecting Spindle Speed Selection

Several factors need to be considered when selecting the appropriate spindle speed for CNC mechanical parts machining. These include:

1. Material Properties

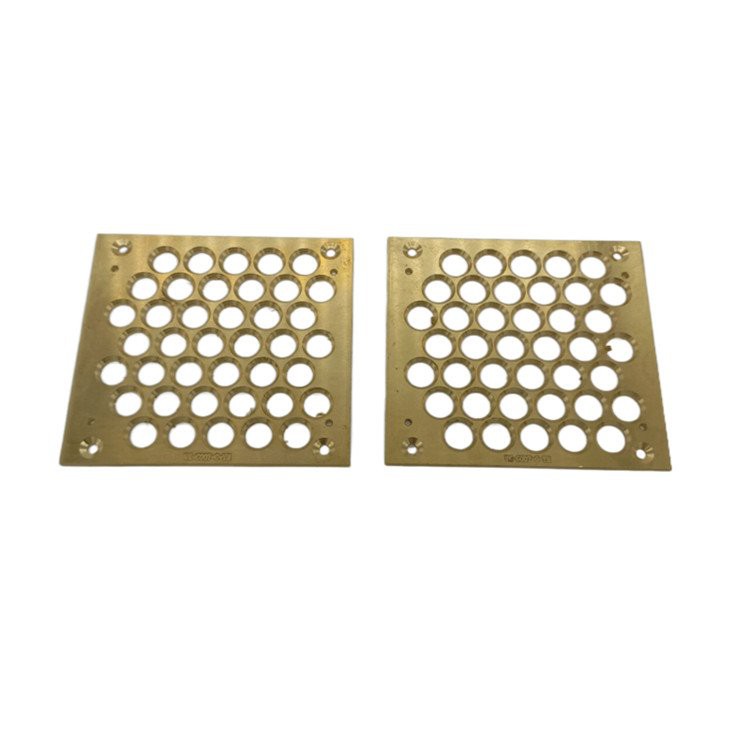

The type of material being machined is one of the most significant factors influencing spindle speed selection. Different materials have different hardness, strength, and thermal conductivity, which require different cutting speeds to achieve optimal results. For example, softer materials such as aluminum and brass can generally be machined at higher spindle speeds compared to harder materials like steel and titanium.

2. Tool Material and Geometry

The material and geometry of the cutting tool also play a crucial role in determining the appropriate spindle speed. Tools made from high-speed steel (HSS) are typically used for lower cutting speeds, while carbide tools can withstand higher speeds and are more suitable for machining harder materials. Additionally, the tool's diameter, number of flutes, and rake angle can affect the cutting forces and chip formation, which in turn influence the spindle speed selection.

3. Machining Operation

The type of machining operation being performed, such as milling, turning, drilling, or grinding, also affects the spindle speed selection. Each operation has its own unique requirements and cutting conditions, which need to be taken into account when determining the appropriate speed. For example, milling operations generally require higher spindle speeds compared to turning operations due to the nature of the cutting process.

4. Machine Capabilities

The capabilities of the CNC machine, including its maximum spindle speed, power, and torque, also need to be considered when selecting the spindle speed. It is important to ensure that the selected speed is within the machine's operating range to avoid overloading the spindle and causing damage to the machine or the tool.

Calculating the Appropriate Spindle Speed

Once you have considered the factors mentioned above, you can use the following formula to calculate the appropriate spindle speed for your CNC machining operation:

[ RPM = \frac{CS \times 12}{\pi \times D} ]

Where:

- RPM is the spindle speed in revolutions per minute

- CS is the cutting speed in surface feet per minute (SFM)

- D is the diameter of the cutting tool in inches

The cutting speed (CS) is a function of the material being machined and the tool material. You can refer to cutting speed charts or consult with tool manufacturers to determine the recommended cutting speed for your specific application.

Example Calculation

Let's say you are machining an aluminum part using a carbide end mill with a diameter of 0.5 inches. The recommended cutting speed for aluminum using a carbide tool is approximately 500 SFM. Using the formula above, you can calculate the appropriate spindle speed as follows:

[ RPM = \frac{500 \times 12}{\pi \times 0.5} \approx 3820 RPM ]

Fine-Tuning the Spindle Speed

While the formula provides a good starting point for selecting the spindle speed, it is often necessary to fine-tune the speed based on the actual machining conditions and the desired results. Here are some tips for fine-tuning the spindle speed:

1. Start with a Conservative Speed

When starting a new machining operation, it is recommended to start with a conservative spindle speed and gradually increase it until you achieve the desired results. This allows you to monitor the cutting process and make adjustments as needed to avoid tool breakage or poor surface finish.

2. Monitor the Cutting Forces

Pay attention to the cutting forces during the machining process. If the cutting forces are too high, it may indicate that the spindle speed is too low, and you may need to increase the speed to reduce the forces. Conversely, if the cutting forces are too low, it may indicate that the spindle speed is too high, and you may need to decrease the speed to improve the tool life and surface finish.

3. Evaluate the Surface Finish

The surface finish of the machined part is another important indicator of the appropriate spindle speed. If the surface finish is rough or has visible tool marks, it may indicate that the spindle speed is too high or too low. You can adjust the speed accordingly to achieve a smoother surface finish.

4. Consider the Chip Formation

The chip formation during the machining process can also provide valuable information about the spindle speed. If the chips are long and stringy, it may indicate that the spindle speed is too low, and the chips are not being broken up properly. On the other hand, if the chips are short and curly, it may indicate that the spindle speed is too high, and the chips are being overheated. You can adjust the speed to achieve the optimal chip formation.

Importance of Selecting the Right Spindle Speed

Selecting the appropriate spindle speed for CNC mechanical parts machining is crucial for several reasons:

1. Improved Quality

By choosing the right spindle speed, you can achieve a better surface finish, dimensional accuracy, and geometric tolerance of the machined parts. This results in higher-quality products that meet or exceed the customer's requirements.

2. Increased Efficiency

Optimal spindle speed selection can significantly improve the material removal rate, reducing the machining time and increasing the productivity of the CNC machine. This leads to cost savings and improved profitability for your business.

3. Extended Tool Life

Using the appropriate spindle speed can also extend the life of the cutting tools, reducing the tooling costs and minimizing the downtime for tool changes. This is especially important when machining hard materials or using expensive carbide tools.

4. Enhanced Safety

Selecting the right spindle speed helps to ensure the safety of the operators and the CNC machine. Operating the machine at excessive speeds can cause tool breakage, workpiece damage, and even pose a risk of injury to the operators. By following the recommended spindle speed guidelines, you can minimize these risks and create a safer working environment.

Conclusion

Selecting the appropriate spindle speed for CNC mechanical parts machining is a complex process that requires careful consideration of several factors, including the material properties, tool material and geometry, machining operation, and machine capabilities. By understanding the basics of spindle speed and using the appropriate calculation methods, you can choose the right speed for your specific application and achieve optimal machining results.

As a supplier of CNC Mechanical Parts, we are committed to providing our customers with high-quality products and technical support. If you have any questions or need assistance with spindle speed selection or any other aspect of CNC machining, please do not hesitate to contact us. We look forward to working with you to meet your machining needs and help you achieve your business goals.

References

- ASME Y14.5-2009, Dimensioning and Tolerancing

- Cutting Tool Engineering Handbook, 4th Edition

- Machinery's Handbook, 30th Edition